Product Description

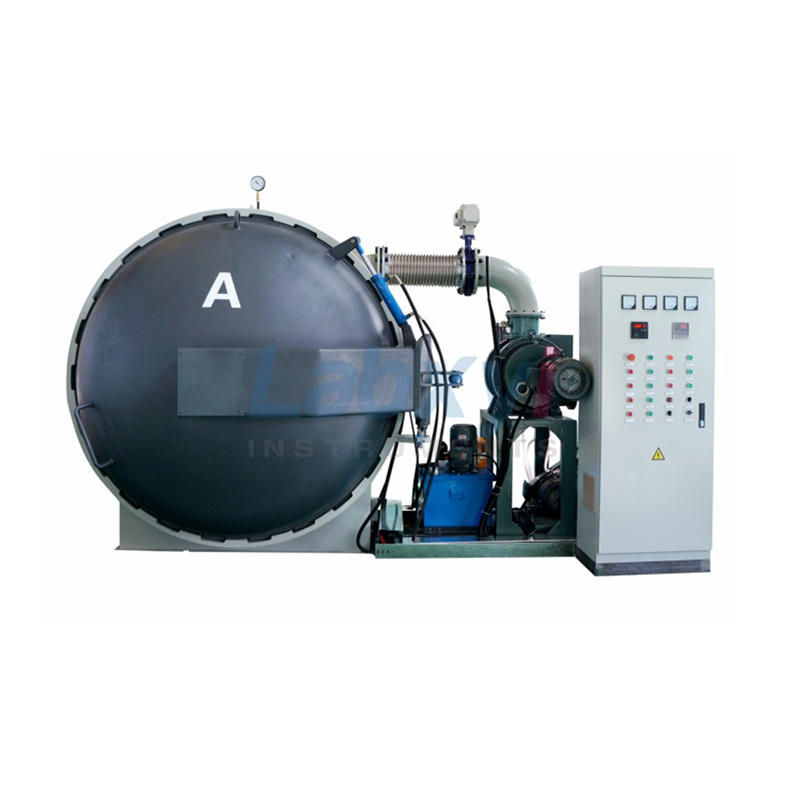

Vacuum atmosphere furnace can work under vacuum and protective atmosphere, and is widely used in heat treatment of cemented carbide, ceramics, powder metallurgy materials; it can also be used for quenching, annealing and brazing of high-speed steel, alloy abrasives, soft magnetic alloys and other materials.

How to choose a suitable vacuum furnace

- Vacuum furnace products are usually divided into three temperatures, 1200℃, 1400℃, 1700℃

- When the actual use temperature is lower than 1200℃, you can choose 1200℃ vacuum furnace products. For this temperature vacuum furnace, we use HRE high temperature alloy resistance wire as the heating element; generally, this type of product is suitable for vacuum annealing of metals and carbon materials.

- When the actual use temperature is higher than 1200℃ and lower than 1400℃, you can choose 1400℃ vacuum furnace products. For this temperature vacuum furnace, we use SIC silicon carbon rods as heating elements; generally, this type of product is suitable for annealing and aging of non-ferrous metals and vacuum sintering of non-metallic ceramic materials.

- When the actual use temperature is higher than 1400℃ and lower than 1700℃, you can choose 1700C vacuum furnace products. For this temperature vacuum furnace, we use MoSi2 silicon molybdenum rods as heating elements; generally, such products are suitable for heat treatment of new materials such as composite materials and nanomaterials.

- The continuous working temperature of the vacuum furnace should be 100℃ lower than the rated design temperature. Correct use can effectively extend the service life of the vacuum furnace.

Selection of gas system

- The vacuum furnace has the function of passing inert gas and is designed with gas inlet and outlet to provide atmosphere protection for samples at high temperatures.

- Gas flow control can select one or more float flow meters to adjust the gas flow

- The gas source can be selected from gas cylinders or pipelines for centralized gas supply (the gas source is generally an accessory prepared by the user)

Selection of furnace size

- Choose the appropriate furnace size according to the volume of the sample. It is recommended that the maximum loading size of the sample be at least 100mm smaller than the furnace size, which is conducive to sufficient heat exchange of the sample.

- Furnace volume 3-1000L is available, and can also be customized according to actual requirements

Vacuum system selection

- The vacuum furnace has flange sealing structure, the furnace door has sealing ring and locking device, and is designed with independent vacuum exhaust port, which can work under vacuum.

- The vacuum system uses trapezoidal O-rings made of wear-resistant silicone to ensure reliable sealing and minimal vacuum leakage.

- Mechanical pressure gauge can display the pressure in the furnace, and digital composite vacuum gauge can be selected to display the vacuum degree digitally

- Different vacuum pumps can achieve different vacuum levels. The prices vary greatly depending on the vacuum level. Generally, they can be divided into molecular pumps, diffusion pumps, Roots pumps, and mechanical pumps. Mechanical pumps can achieve a vacuum degree below 500 Pa. Roots pumps combined with mechanical pumps can achieve a vacuum degree below 50 Pa. The vacuum degree of the diffusion pump unit can reach 6×10² Pa.