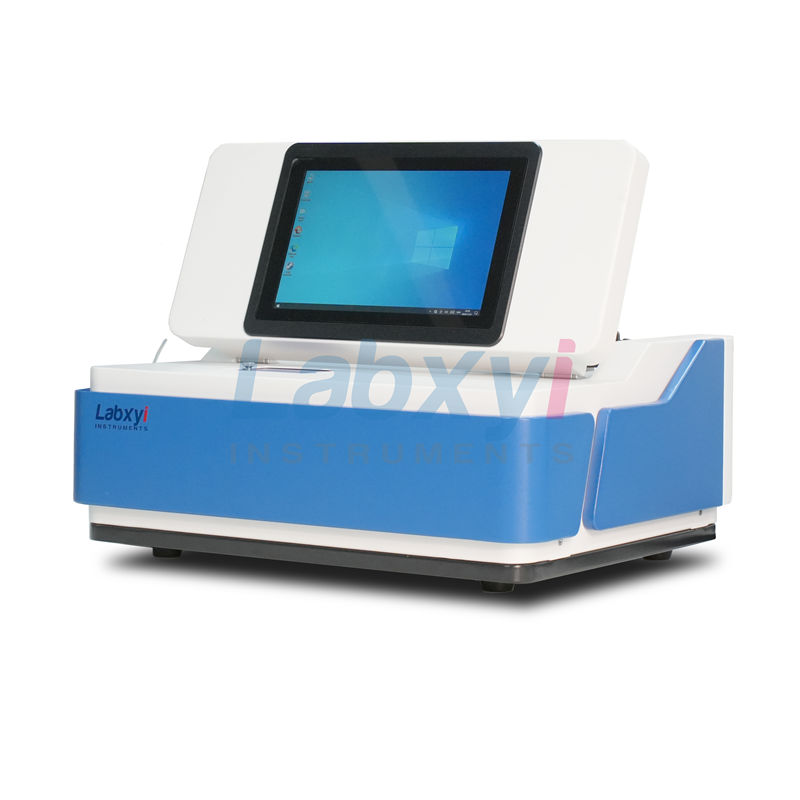

WOA-400B Fully automatic infrared oil content analyzer of water

WOA-400B Fully automatic infrared oil content in water analyzer comply with national standards Water quality-Determination of petroleum, animal fats arvegetable oils-Infrared spectrophotometry

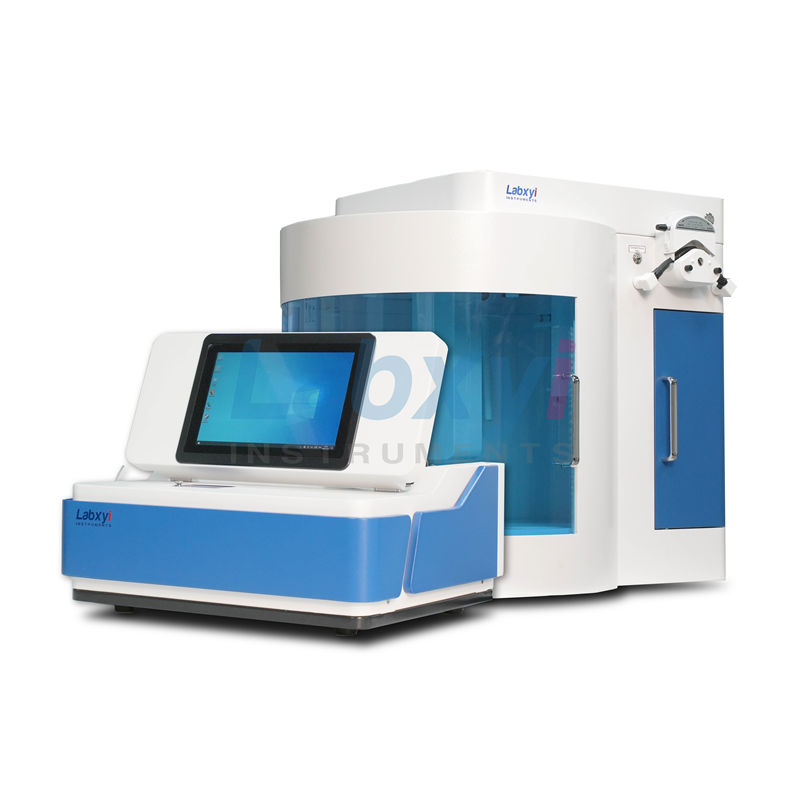

There is no need for the operator to contact perchloroethylene, i.e., automatic sampling, automatic extraction, automatic water removal and impurity removal, automatic measurement, automatic cleaning, automatic drainage and data storage.

Purpose and Reference Method E

Used for laboratory determination of oil content in industrial waste water.

Core Technology of infrared oil content analyzer

| Complete separation of waste gas treatment equipment reagents from water

|

100 times use for Core oil-water separator technology One film

|

Accurately measures with a high precision syringe for a hundred times of One film

|

Free switching of magnesium silicate column

|

Technical Characteristics of infrared oil content analyzer

- Automated operation of sample processing, system cleaning, oil content determining andanalyzing. The extractant should be fullly isolated in alI processes such as storage, extraction, analyzing and waste discharge.

- The number of samples that can be processed continuously in a single batch≥10;

- Injection mode: automatic/manual injection mode, can be quickly switched; in automaticmodecan continuously measure the oil content in water from the connected pre-treatment unit;in manual mode, can be used for stand-alone operation to measure the oil content in waterthat extracted outside the pre-treatment unit;

- Tetrachloroethylene extraction method should ensure the extractionefficiency≥95%;

- Automatic measurement of water sample volume,error≤2%;

- Can prepare solutions of different concentration points on the curve, automatically

- generate the standard curve; can identify unknown high concentration sample and automatically

- di lute according to the set concentration threshold; can set the di lution ratio.

- With insufficient alert function on extractant.

- Pre-treatment unit

- Using a 100OmL dedicated and graduated extraction bottle, with scale markings and forextraction use only; can be used for field sampling, no need to transfer water samples andcan be directIy tested on the machine

- The extraction bottle shall be made of non-lipophilic material; a special sampling case shallbe equipped to meet the requirements of on-site sampling and sample transferring.

- Realtime accurate positioning of water sample cup; the reagent filling, sample extractionand waste discharge should all be equipped with independent pipelines,which do not interferewitheach other.

- Health and safety:Extraction and other operations do not require personnel involvement anddo not come into contact with reagents. Standard fume hood operations ensure personnel’s health.

- High precision automatic injector: Reagent 0~600ml can be set arbitrarily, with automaticdilution at high concentrations, automatic quality control sample preparation,and automaticone click calibration for curve making;

- One click calibration: Standard infrared oil standard filters can be used for one click calibration, with multiple calibrations without the need for reagents. At the same time,single point and multi-point automatic detection and calibration are convenient and fast;

- One click completion: Turn on the machine and complete multiple water sample tests with oneclick, without any other operations in between, reducing the workload of operators;

- One click completion: Turn on the machine and complete multiple water sample tests withone click, without any other operations in between, reducing the workload of operators; Coreoil water separation technology: The effective filtration area of the anti blocking anddemulsification membrane is more than 45mm, and the double membrane separation replacesanhydrous sodium sulfate. One membrane can be used 100 times, and there is an audible andvisual alarm when the membrane is broken;

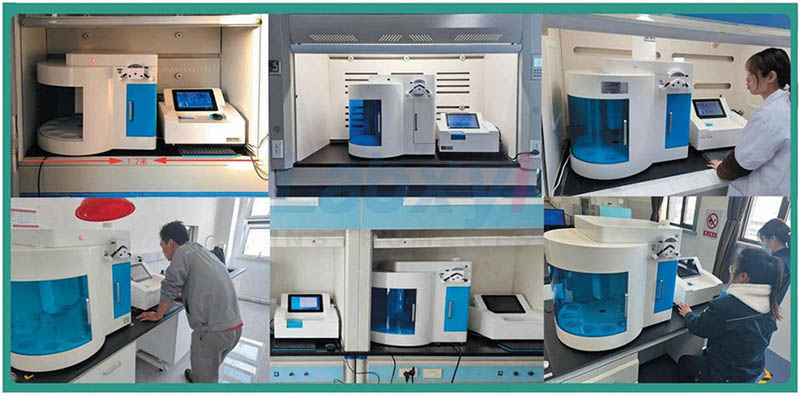

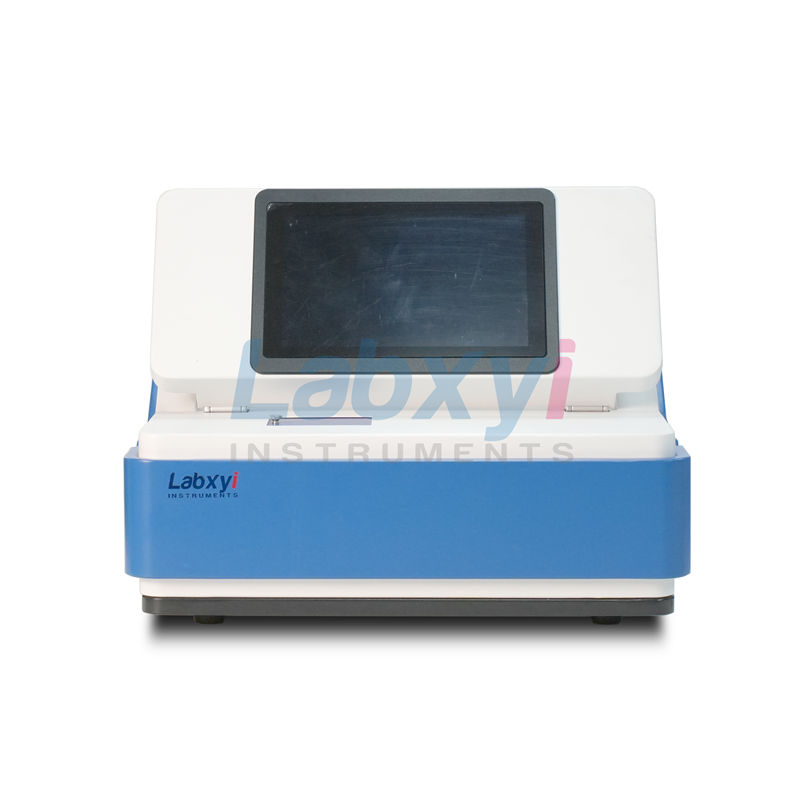

- Built-in 12 inch touch computer, Windows full system control, USB interface with intelligent information processing, storage, printing, small size can be placed in a conventional standard1.2 meterfume hood;

- The dual system of the ultraviolet infrared oil measuring instrument switches the oilmeasuring instrument software with one button, and has a software copyright certificate.It can switch between semi-automatic and fully automatic operations with one button;

- Unlimited automatic filling, replacement, and emission of magnesium silicate meet thenational standard. One replacement can automatically detect total oil, petroleum, or animaland vegetable oils, and automatically display the remaining amount of magnesium silicate;

- Three wave number characteristic peak spectrogram scanning, automatic scaling of thespectrogram, and the accuracy of sample concentration can be traced through absorption peakscanning spectrogram as evidence;

- Fault self inspection: automatic detection of pre processing and host failure upon startupsound andlight alarm forfaults;

- Automatic separation and collection of wastewater and waste tetrachloroethylene, automaticdetection and display of reagent residue, and upgraded automatic recovery and reuse of waste1iquid;

- The mobile app can remotely operate and monitor, allowing for the appointment of new watersamples without stopping the ongoing process without any impact, and the infinite cycle ofsample preparation does not stop;

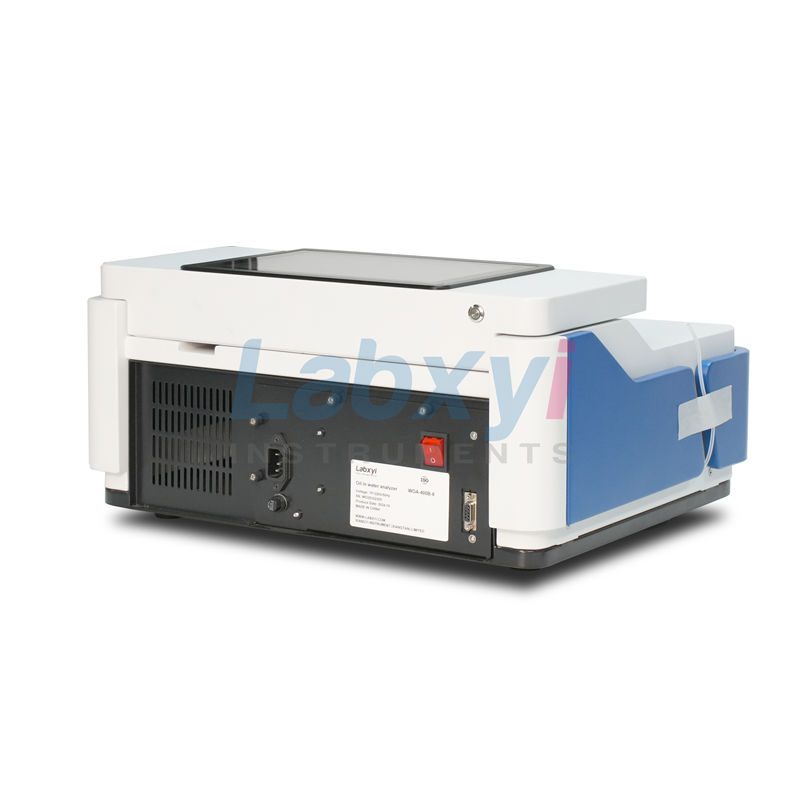

- Directly access and upload to the laboratorydata platform through the RS486 communication protocol of Instrument data;

- Good baseline stability: automatic real-time adjustment of zero point (eliminating theimpact of baseline drift);

Specifications

| MODEL | WOA-400B |

| Instrument detection limit | DL<0.02mg/L

(3x standard deviation calculated for 11 blank measurements) |

| Measuring range | 0.0-100% pure oil

(diluted or enriched) |

| repeatability | RSD≤1% |

| Measurement accuracy | Error<±2 % |

| correlation coefficient | R≥0.9999 |

| Take the volume of water samples | 5ml–600ml or

5ml–1000ml |

| Measure the sample volume | Continuously test 6-16 samples |

| Amount of perchloroethylene extracted | 0.01-25ml integer multiples |

| Automatic detection time for individual samples | 3-8min |

| Wavenumber range | 2400cm-1~3400cm-1

(i.e. 2941nm~4167nm) |

| Absorbance range | 0.0000~2.0000AU

(i.e. transmittance 100~1%T) |

| Wavenumber accuracy and wavenumber repeatability | ±1cm-1 |

| Net weight of the main unit | 22kg |

| Use a power source | 220 V/50Hz, 50VA |

| Temperature and humidity of use | Temperature range 1°C-40°C, humidity ≤80% |

| Dimensions | 1205×550×655mm (L*W*H) |