Scope of application

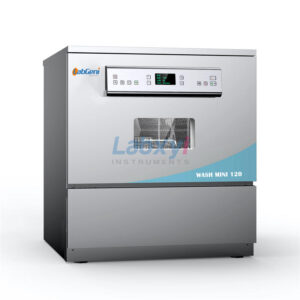

Automatic washing machine, used in food, agriculture, pharmaceutical, forestry, environment, agricultural product testing, laboratory animals and other related fields to provide glassware cleaning solutions. Used for cleaning Erlenmeyer flasks, volumetric flasks, pipettes, injection vials, test tubes, petri dishes, etc.

Qualification

- Passed ISO9001 quality management system certification and ISO14001 environmental management system certification

- Pass the EU CE certification

- Test the residual water (PH, TOC, conductivity) report after cleaning by an authoritative organization

- Pass the third party residue test report

- The company’s products have more than 5 patents

- The above provides a copy of the certification certificate, test report and patent certificate

Technical performance

- Wash start delay function: The instrument comes with time start and timer start functions, can improves the work efficiency.

- Operation interface: Chinese and English menu operation interface, multi-level password protection.

- Use stainless steel metal waterproof keyboard panel, waterproof grade: IP65, humanized interface layout, buttons are laser-engraved,corroded and high-quality durable, long-time use will not fall off and wear.

- The viewing window is made of pure-screen float tempered glass material, which has high durability, clear texture and better sound insulation.

- OLED module color display, self-luminous, high contrast, no viewing angle limit.

- Microcomputer intelligent control, 485 hub, optocoupler isolation, original imported chip, with better linearity, segment interference, signal long-distance transmission protection and other functions.

- The instrument has RS-232 printing interface, USB interface, can be connected to computer, printer, U disk, etc., and built-in storage chip to record cleaning data.

- Automatic door opening, ITL induction technology, the door cannot be opened during the cleaning process, the door positioning buckle will be automatically opened after the cleaning is completed, and the door will be pushed to the designated position, and the positioning buckle will automatically return after the door is opened, which helps after cleaning Cooling and automatic drying of utensils.

- Automatically close the door, ITL induction technology, the door buckle and positioning buckle will automatically close after connecting, no need to push manually.

- Automatically identify the basket and automatically adjust the water volume.

- The instrument is equipped with a variable frequency start function, the frequency of the cleaning circulation pump is adjustable, and the speed of the motor can be adjusted at the same time to prevent the instantaneous impact of the circulating water on the utensils during the cleaning process and the utensils are damaged.

- The circulating pump has its own overheating protection device to extend the service life.

- Built-in pipeline heating tube, clean and tidy in the cleaning chamber; 6D water pipeline design, zero dead angle welding technology, prevent pollution and residual risks, and ensure that the instrument meets GMP and FDA specifications.

- The circulation system is equipped with pressure monitoring and anti-foam cleaning technology to ensure the cleaning effect.

- The sprinkler system is equipped with speed monitoring, the speed range can be set, and the obstacle will alarm.

- Modular basket frame design, can be placed on the upper and lower layers at the same time, can also be placed on any layer, without changing the basket structure.

- The injection type basket frame adopts ICA module design, which can be freely interchanged. The basket frame and the basket frame are connected by quick-plug, and there is a positioning groove to fix the basket frame, which is more flexible and convenient to use.

- The new water inlet method at the back of the cleaning chamber improves the restriction of the original top water inlet method; there are at least two water outlets on the back to meet the needs of the upper and lower two-layer modular baskets. Each outlet has an automatic closing mechanical valve device.

- Built-in conductivity monitoring system, full-process conductivity monitoring, parameter setting of rinsing water, automatic monitoring of rinsing water quality and intelligent adjustment of cleaning procedures.

- Original imported double-layer explosion-proof electronic safety water inlet pipe, pressure-resistant and temperature-resistant, not easy to scale, with anti-leakage monitoring valve, the instrument will automatically shut off the solenoid valve when it fails to cut off the water source from the source to ensure laboratory safety.

- Remarks: * means the parameters must be met.

Basic parameters

| Model | WASH EXP 170 | WASH EXP 170D |

| Dry system | N/A | Hot air dry |

| Water inlet requirements | tap water/pure water | tap water/pure water |

| power supply | 220V/380V | 220V/380V |

| Volume of cleaning chamber | 170L | 170L |

| Circulating pump power | 750W | 750W |

| Heating power | 4KW/9KW | 4KW/9KW |

| Circulation system speed | 500L/min, providing strong cleaning ability | 500L/min, providing strong cleaning ability |

| Material | Inner tank 316L mirror stainless steel, Outer shell 304 brushed stainless steel or plastic spraying process | Inner tank 316L mirror stainless steel, Outer shell 304 brushed stainless steel or plastic spraying process |

| Program control | 35 standard cleaning procedures & 100 custom procedures, two layers of cleaning baskets can be placed, upper and lower layers can clean 100ml volumetric flasks in one time | 35 standard cleaning procedures & 100 custom procedures, two layers of cleaning baskets can be placed, upper and lower layers can clean 100ml volumetric flasks in one time |

| Cleaning capacity | 476 injection vials, 42 100ml volumetric flasks, and 238 pipettes can be cleaned in one time | 476 injection vials, 42 100ml volumetric flasks, and 238 pipettes can be cleaned in one time |

| Temperature display accuracy | 0.1℃ | 0.1℃ |