Chemical vapor deposition (CVD) tube furnace refers to a method of synthesizing coatings or nanomaterials by reacting chemical gases or vapors on the surface of a substrate. It is the most widely used technology in the semiconductor industry for depositing a variety of materials, including a wide range of insulating materials, most metal materials and metal alloy materials.

Product Description

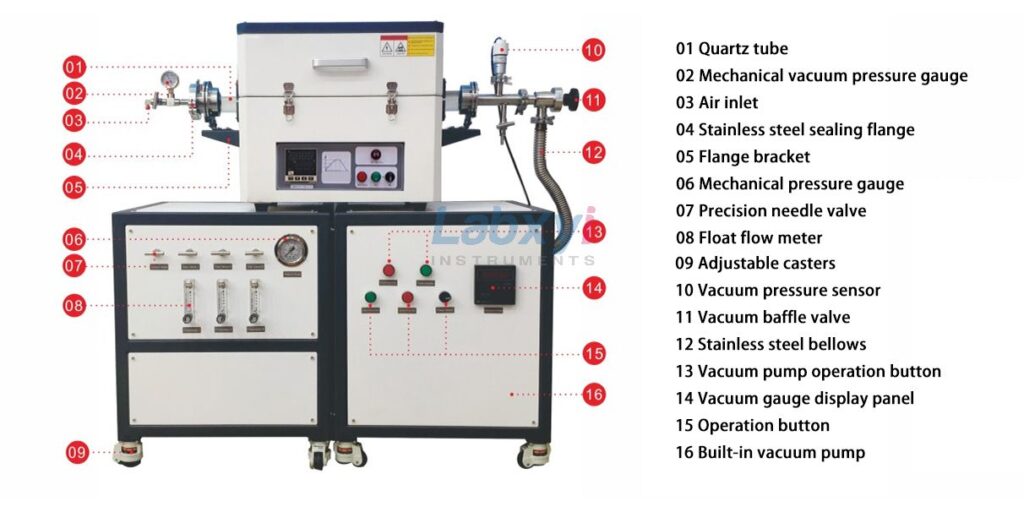

The CVD tube furnace system consists of a heating system, a vacuum acquisition system and a gas circuit system.

Tube furnaces can choose different tube diameters and constant temperature zone lengths. The stainless steel sealing flanges at both ends of the furnace tubes can also choose high vacuum flanges and low vacuum flanges.

The vacuum acquisition system can select different vacuum pumps according to the test requirements. The vacuum degree of the rotary vane mechanical vacuum pump is ≤5Pa, and the vacuum degree of the molecular pump vacuum unit is 1×10-4Pa.

The gas supply system can choose 3-way float manual and 3-way automatic mass flow system.

For vacuum measurement, a digital compound vacuum gauge or a Pirani vacuum gauge is used.

The thermostat’s built-in RS485 digital communication port and USB adapter as an optional configuration can be connected to a PC for remote control and monitoring of the system, and can also save or export test results.

The product complies with EU CE standards.

Technical Parameters

| model | VTF-CVD2512 | VTF-CVD4012 | VTF-CVD6012 | VTF-CVD8012 | VTF-CVD10012 | VTF-CVD12012 | |

| Furnace tube size | φ25×800mm | φ40x800mm | φ60x 800mm | φ80x800mm | φ100x800mm | φ120×800mm | |

| Rated temperature | 1200℃ | ||||||

| Operating temperature | 1100℃ | ||||||

| Heating zone size | 300mm | ||||||

| Supply voltage | 220V/1.8KW | 220V/1.8KW | 220V/2.6KW | 220V/2.6KW | 220V/2.6KW | 220V/5KW | |

| Heating elements | HRE Alloy Resistance Wire | ||||||

| Furnace material | Polycrystalline inorganic alumina ceramic fiber material prepared by wet vacuum filtration molding | ||||||

| Furnace tube material | Quartz tube | ||||||

| Temperature control accuracy | ±1℃ | ||||||

| Temperature measuring element | N-type thermocouple | ||||||

| Temperature control instrument | Intelligent microcomputer PID temperature control instrument, SCR/SSR control, PID parameter self-tuning function; 30 programmable time periods, program heating, program insulation, program cooling | ||||||

| Heating rate | 1-25℃/min freely adjustable | ||||||

| Furnace structure | Furnace temperature control integrated structure, furnace opening and closing; double-layer shell, air circulation and heat insulation | ||||||

| Sealing performance | Both ends of the furnace tube are equipped with stainless steel metal flanges and high-temperature PTFE gaskets. They can work under vacuum, and the vacuum degree is ≤5pa (rotary vane vacuum pump) | ||||||

| Atmosphere performance | There are air inlet and air outlet at both ends of the flange. The pressure gauge is installed on the metal flange. The precision needle valve can adjust the air inlet and outlet volume. Protective gases such as nitrogen, argon, and hydrogen can be introduced. | ||||||

| Device protection | Modular control, which will send out sound and light alarm signals for over-temperature and broken circuit in the working process, and automatically complete the protection action | ||||||

| Security protection | The equipment is equipped with a circuit breaker, which will automatically pop open in the event of a short circuit or leakage, thus protecting the equipment and operators. | ||||||

| shell | High-quality cold-rolled steel plates are processed by CNC machine tools, and then welded, ground, polished, phosphated, pickled, and electrostatically sprayed with plastic powder on the surface. | ||||||

| Quality Certification | IS09001 CE SGS TUV | ||||||

| Standard Configuration | 1. Furnace body 1 set 2. Temperature controller 1 set 3. Power cord 3 meters 4. Thermocouple 1 piece 5. Instruction manual 1 set 6. Furnace hook 1 set 7. High temperature gloves 1 pair 8. Pipe plugs 2 pieces 9. Sealing flange 1 set | ||||||

| Optional Accessories | 1. Optional rotary vane vacuum pump (vacuum degree ≤ 5pa) 2. Optional digital vacuum gauge (1.0×10°-1.0×10’pa) 3. Optional float flowmeter (range 60-600m/min) 4. Optional quartz boat | ||||||

-300x300.jpg)