Industrial analysis of coal includes the determination of moisture, ash, volatile matter and fixed carbon. Traditional methods require the use of muffle furnaces, ovens and other equipment, which are cumbersome and have large errors. Thermogravimetric analysis is a common method for evaluating the thermal stability of coal. It is widely used in coal analysis, mainly used to study coal pyrolysis, combustion characteristics, volatile matter release, ash residue and reaction kinetics.

1.Test Principle

When coal is heated in an inert gas, it undergoes a pyrolysis process: volatiles gradually precipitate, and fixed carbon and ash remain. Thermogravimetric analyzers monitor the mass changes of coal samples during the heating process in real time to plot mass and temperature as well as DTG differential curves, thereby analyzing their pyrolysis characteristics.

2.Experimental test steps

- Sample preparation: Grind the coal sample into uniform powder and take 15-30 mg of sample to avoid heat transfer differences due to uneven particles.

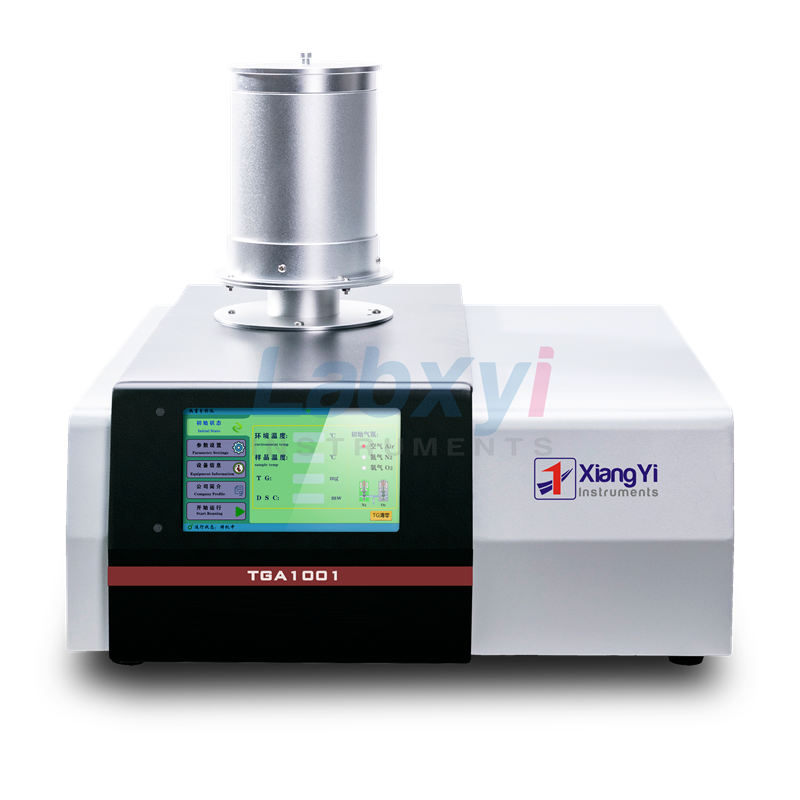

- Equipment: TGA1001 thermogravimetric analyzer

3.Equipment parameter setting

Atmosphere: high purity nitrogen (to avoid oxidation reaction and simulate pyrolysis environment), gas flow rate is usually 50ml/min

Temperature program: room temperature to 800°C (adjust according to experimental requirements) Heating rate recommended 20°C/min

- During the test, spread the sample evenly on the bottom of the crucible to avoid accumulation, run the thermogravimetric analyzer equipment program, and record the TG changes.

.jpg)

5.Data Analysis

The coal pyrolysis stage is mainly divided into three stages as the temperature increases.

5.1 Drying and dehydration stage (room temperature – 200 °C) The adsorbed water and part of the bound water are removed. As can be seen from the figure, the weight loss from 50 °C to 200 °C is 7.64%.

5.2 Volatilization analysis stage (200°C-600°C) is also the main pyrolysis stage, where organic matter undergoes cracking and volatilization to generate tar, CH4, etc. The concentration is always about 42.6%.

5.3 Final decomposition stage (600°C-800°C) The carbon content further decomposes and then stabilizes.

3.The role of thermogravimetric analyzer in measuring thermal stability of coal

- Evaluate the thermal stability of coal. Thermogravimetric analyzer can evaluate the thermal stability of coal at high temperature by measuring the mass change of coal sample during heating.

- Analyze the pyrolysis rate and weight loss. As the temperature rises, the pyrolysis rate of coal will change. Thermogravimetric analyzer can accurately measure the mass change rate of coal at different temperatures, that is, the pyrolysis rate. By analyzing the pyrolysis rate curve, we can understand the speed of coal pyrolysis reaction.

- Evaluate the effect of additives on the thermal stability of coal. In order to improve the thermal stability of coal, some additives are sometimes added. Thermogravimetric analyzers can be used to evaluate the effect of these additives. By performing thermogravimetric analysis on coal with and without additives, the difference in mass-temperature curves is compared.

4.Precautions during the experiment

- Sample uniformity: If the sample particles are not uniform, the test results may fluctuate.

- Heating rate: Adjust the appropriate heating rate. Too fast or too slow a rate will affect the test results and reaction details.