Module design

- User can purchase the closed-circuit system module separately for organic solvent processingin future.

- Quick-release design, closed-circuit system modulecan be removable and connect in one second, use can use air compressor or inert gas to process water-based or organic solvent in one machine.

- Spray dryer can be put on table and also placed in floor to convenient use using.

- Can be connect to Nitrogen generator* or nitrogen bottle.

- Developed base on Labspray® SD-18A flagship mini spray dryer with it excellent configurationand performance.

Main configuration

Inert gas closed loop module main include:

- Double condenser for solvent cooling and recovery

- Can connect to tap water or circulation chiller* base on demand.

- Advance oxygen monitor system to detect the oxygen level make sure easy and more safety.

- Advance bag filter system, full stainless steel chamber, used U.S. Donaldson brand filter core which is best and easy to replace and clean.

Meticulous & stable

- Professional designers surgeon design, patent application has been submitted

- Full body high quality stainless steel material

- Mechanical parts grinding secret agents, only the pursuit of perfection

- S. spray brand Two fluid spray nozzle, SS316 material

- Deblock interval adjustable

- Power supply & Fan imported from Taiwan

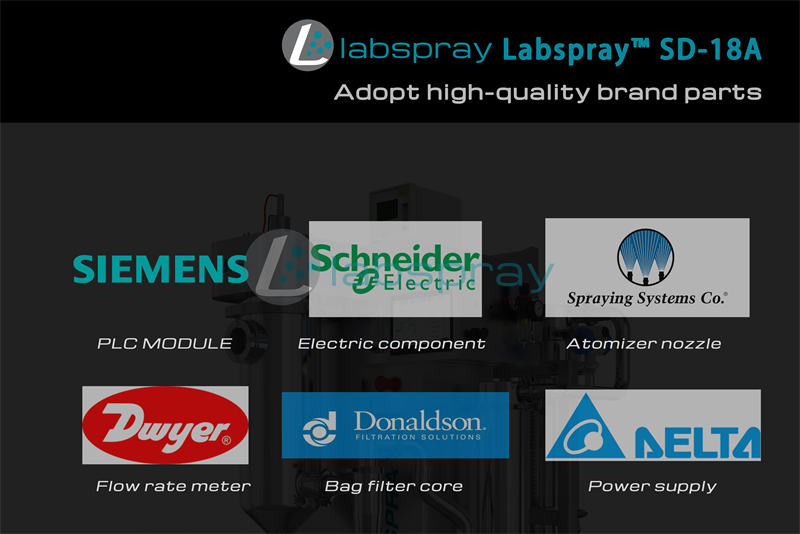

- Siemens PLC & Schneider electric components

- LCD touch display from Taiwan

- With USB interface to export data to computer

- ISO 9001 & ISO 14001 certificated

U.S. Spray two-fluid atomizer

- American Spray double fluid nozzle is an excellent high precision spray nozzle. The instrument uses an external mixing nozzle, the air and liquid streams can be individually controlled to effectively spray highly viscous liquids and suspended abrasives.

- Double fluid nozzle is installed at the center of the top of the air distributor and sprays directly down into the tower. The feed enters at a minimum pressure through a tube inlet of the nozzle and is atomized with compressed air.

AIR SUPPLY SYSTEM

- Medium pressure blower imported from Taiwan

- Fan is the internal mechanical structure of the rotor

- The air supply system of the instrument adopts frequency conversion control to realize the stepless adjustment of the air volume, so as to meet the requirements of different process spray drying experiments.

Component instruction

APPLICATION

- SD-18APRO small spray drying apparatus can be used for drying flammable organic solvent as well as aqueous solution and suspension. It is suitable for the experiment and production of uniform powder. Such as: pharmaceuticals, dyes, pigments, food and beverage, milk, egg products plants and vegetable products, heat sensitive materials, plastics, polymers, resins, ceramics, perfume, soap, detergent, blood, adhesives, oxides, textiles, bone, teeth etc.

- SD-18APRO is particularly applicable to the laboratory for liquid material directly into micro powder, without materials filtration, concentrating and crushing before drying, applicable for all solutions such as emulsion, suspension.

SPECIFICATIONS

| Model | SD-18A pro loop mini Spray Dryer (Upgrade of sd-500/sd-501) |

| Max evaporator capacity | 2000ml/h |

| Pump feeding rate | 50~2000ml/h adjustable |

| Control system |

|

| Inlet air temperature | 30 ~ 250°C (control precision ±0.5°C) |

| Outlet air temperature | 30 ~ 100°C (control precision ±0.5°C) |

| Dry air flow rate | Delta inverter governor , 0~70m3/h adjustable |

| Temperature sensor | PT-100 for inlet and outlet temperature |

| Spray system | U.S. spray system original 0.7mm Two-fluid nozzle atomizer

0.4mm & 1.5mm size is optional |

| Particle size | 1 ~ 25um |

| Avg drying time | 0.8 ~ 1.5s |

| Automatic block device | Automatic deblock function, frequency 0~60s adjustable

Manual deblock function |

| Oxygen detect system | Ensure that oxygen concentration is less than 3% before starting the feed (value can be set) |

| Pressure detect range | 0-100Kpa |

| Exproof module | More than 3Kpa automatic pressure relief (value can be set) |

| Exproof film | Automatic |

| Oxygen detect range | 0-100% (accuracy 0.1) |

| Electrical standard | Schneider |

| Quick release | Temperature meter, air piping and power supply |

| Dry chamber size | D 204mm, H 640mm |

| Bag filter size | D 133mm, H 550mm |

| Condenser size | D 159mm * H 830mm X 2 |

| Exhaust pipe | Diameter 51 mm |

| Power supply | AC220V, 50 ~ 60Hz |

| Heating power | 3.0kw, heater material 2520 special stainless steel |

| Material | Whole body stainless steel |

| Weight | 140 kg |

| Dimensions(H×W×D) | 1000mm×1000mm×1200mm |

BRAND OF MAIN PARTS

| Item Name | Brand |

| Nozzle | U.S. spray system ANSI316 |

| PLC | Siemens S7-200PLC |

| Touch screen | Taiwan MHI |

| Fan motor | Taiwan Delta Inverter fan |

| AC contactor | Schneider |

| Intermediate relay | Schneider |

| Air switch | Schneider |

| Button | Schneider |

| Socket | Aviation socket |

| Solid state relay | TWITEC |

| Rotameter | U.S. Dwyer |

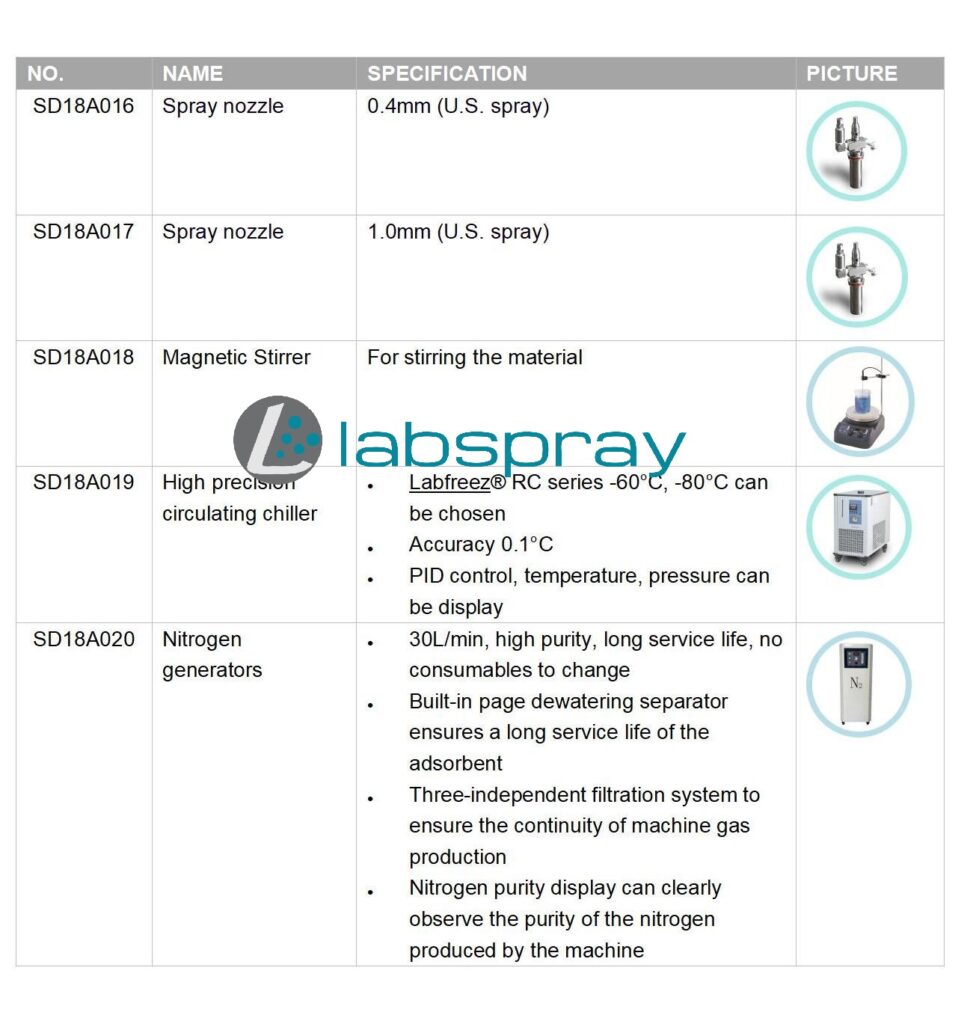

PTIONAL LIST