Applications:

It is widely applied to industries of electronic material, magnetic material, biological medicine, ceramic glaze, metal powder, nonmetallic minerals, new materials and etc.

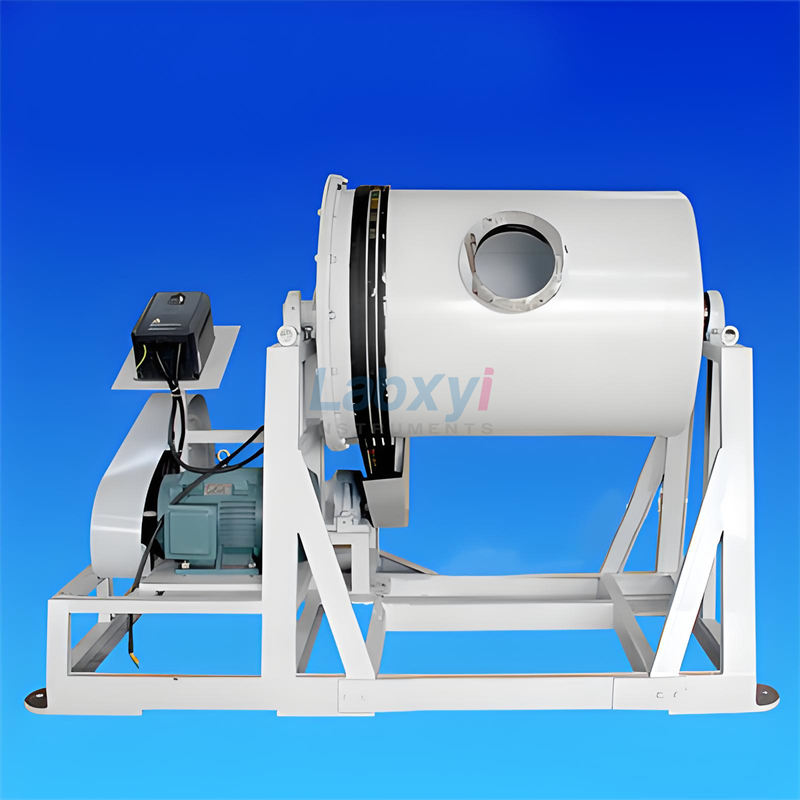

Overview

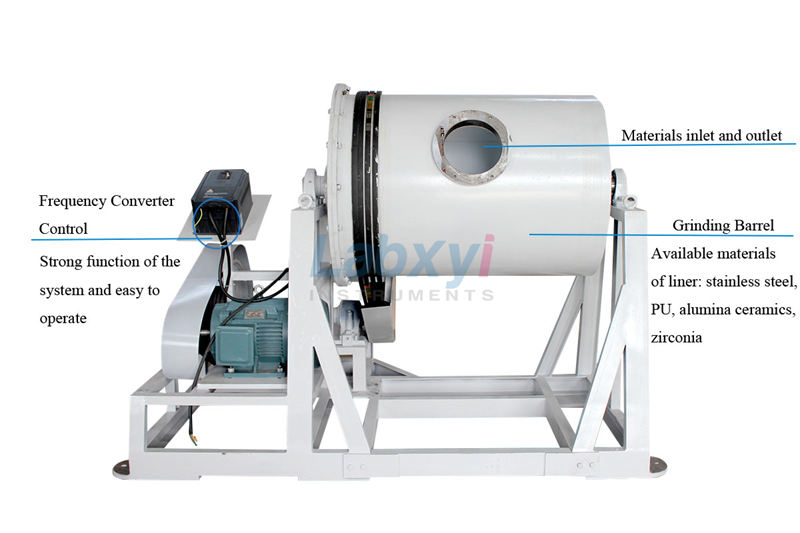

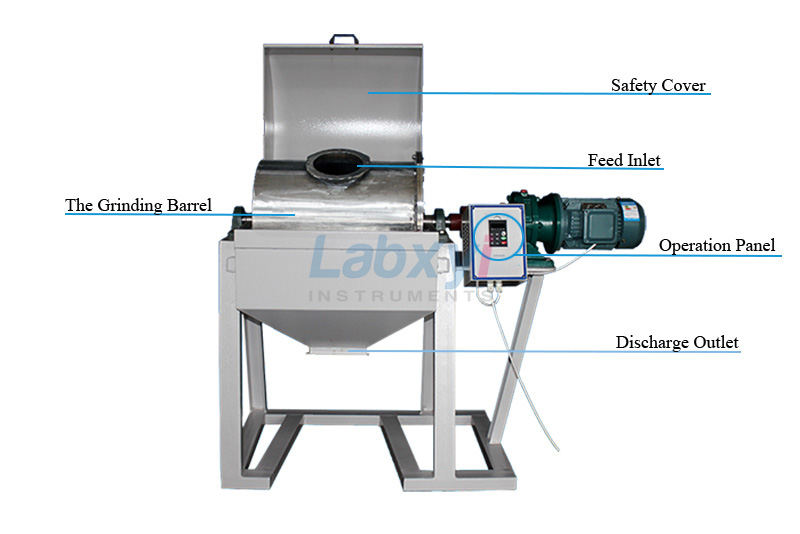

Large roll ball mill is a kind of equipment used for ultra-fine grinding and mixing for batch production, which is also called rolling machine altar. The machine is preferred equipment for scientific research, teaching, experiment and production due to its advantages such as beautiful design, compact structure, easy operation, high efficiency, and uniform granularity. It is widely applied to industries of electronic material, magnetic material, biological medicine, ceramic glaze, metal powder, nonmetallic minerals, new materials and etc.

Working Principle

When ball mill works, the grinding media and the materials of the cylinder are rotated to a certain height. Due to the gravity, they fall down from the tube wall. The materials are crushed by impact action of the grinding media, and friction and shearing action of grinding media’s rolling and sliding.

Advantages

Optimal design of rotating speed is adopted in the machine, where mill jar is dragged to rotate by rubber roller, balls inside the jar make incline flow movement and disperse materials, thus it obtains best effects of grinding. As result, materials are ground to micron powder. Timing control panel is adopted in the machine with controlling functions of pausing and cumulative timing, and you may set working time according to requirement at any time. It saves time and labor, and is easy for operating.

Feature

The machine is extensively applied to in the fields of Geology, Mining, Metallurgy, Electronics, Construction Material, Ceramics, Chemical Engineering, Light Industry Medicine, Environmental Protection etc.

Technical Parameter

| Main Parameters of Large Roll Ball Mill | ||||||||

| Model No. | Volume (L) |

Rotate Speed Range (rpm) |

Material Capacity (L) |

Power Supply | Available Jars | Feed Size (mm) |

Output Granularity (mesh) |

Adjustable Mode of Rotate Speed |

| RBM-100L | 100 | 20~45rpm | 35 | 2.2KW/380V | Carbon Steel, Stainless Steel, Nylon Liner, Alumina Ceramic Liner, PU(polyurethane) Linner, PTFE Liner. |

≤20 | ≥300 | Frequency adjuster or Fixed setting for buyer’s options |

| RBM-200L | 200 | 20~40rpm | 70 | 4KW/380V | ≤20 | ≥300 | ||

| RBM-300L | 300 | 20~38rpm | 105 | 5.5KW/380V | ≤20 | ≥300 | ||

| RBM-500L | 500 | 20~36rpm | 175 | 7.5KW/380V | ≤20 | ≥300 | ||

| RBM-1000L | 1000 | 20~34rpm | 350 | 11KW/380V | ≤30 | ≥300 | ||

| RBM-2000L | 2000 | 20~34rpm | 700 | 22KW/380V | ≤30 | ≥300 | ||