DESCRIPTION

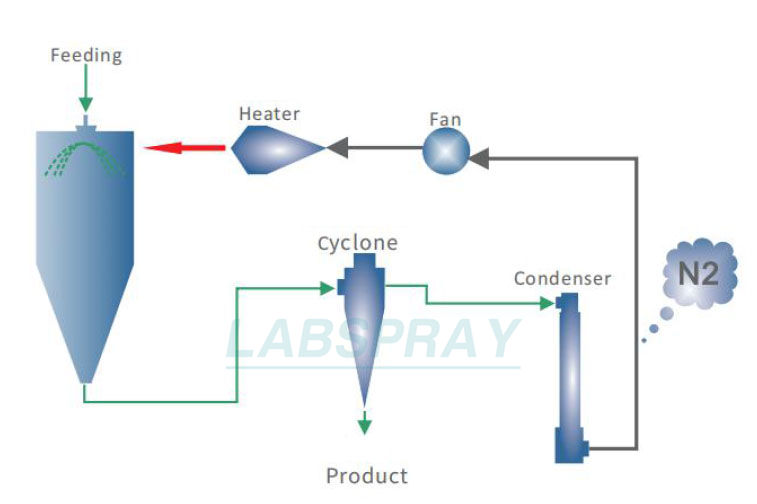

LABSPRAY MINI LOOP is specially designed for organic solvents and uses an inert gas medium formed by circulating nitrogen to replace the usual air medium for spray drying. In addition to recovering products, organic solvents can also be recovered.

This closed-loop spray system is specially designed for the low flash point or slightly toxic, flammable and explosive characteristics of organic solvents. It is an ideal closed-loop dryer for laboratory small-scale to pilot-scale tests. , The drying of toxic materials and oxidizable materials provides a new and reliable method.

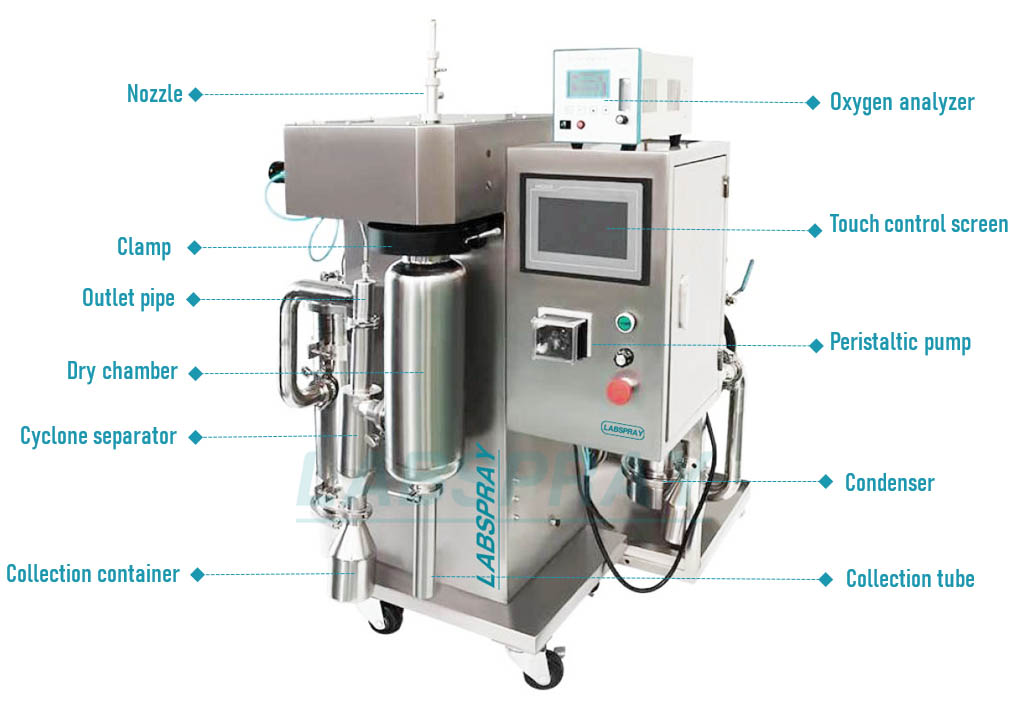

COMPONENTS OF LABSPRAY MINI LOOP

APPLICATIONS

Spray drying can be used in a wide range of applications where the production of a free-flowing powder sample is required. This technique has successfully processed materials in the following areas:

Beverages • Flavours and Colourings • Milk and Egg Products • Plant and Vegetable Extracts • Pharmaceuticals • Heat Sensitive Materials • Plastics • Polymers and Resins • Perfumes • Ceramics and Advanced Materials •

Soaps and Detergents • Blood • Dyestuffs • Foodstuffs • Adhesives • Oxides • Textiles • Bones, Teeth and Tooth Amalgam and many others. Most solutions and suspensions can be spray dried providing that the resulting product has the characteristics of a solid material.

FEATURES

- Color LCD touch screen parameter display: air inlet temperature/air outlet temperature/peristaltic pump speed/air volume, etc.

- Touch screen control: one-button start-up, setting spray process parameters, the process running animation can be clearly displayed on the touch screen;

- Manual control: If you need to adjust the process parameters during the experiment, you can easily switch to the manual state, and the entire experiment process is dynamically displayed on the color touch screen (animation).

- Spraying, drying and collecting parts are made of high-quality stainless steel, so that the drying process can be carried out in a pollution-free environment.

- Atomization structure of two-fluid spray, whole machine is made of high-quality stainless steel, compact design, no auxiliary equipment is required.

- Design of drying temperature control adopts real-time regulation PID constant temperature control technology, ensure accurate temperature control at ±0.5°C.

- In order to keep the sample pure, it is equipped with an air inlet filter.

- Feeding volume can be adjusted by the feeding peristaltic pump, and the minimum sample volume can reach 50ml.

- Finished dry powder after drying has a relatively uniform particle size, and more than 95% of the dry powder is in the same particle size range.

- Equipped with an oxygen content detection instrument, which can detect the oxygen content inside the equipment at any time to ensure safe operation.

TECHNIACL SPECIFICATIONS

| MODEL | LABSPRAY MINI LOOP |

| Inlet air temperature | 30~300°C (accuracy ±0.5°C) |

| Outlet air temperature | 30~200°C (accuracy ±0.5°C) |

| Control way | Intelligent PLC control, Real time PID temperature control, display inlet temperature, outlet temperature |

| Drying time | 0.8s ~ 1.0s |

| Feed rate | 50 ~ 1500ml/h |

| Fan motor mode | Suction |

| Solvent recovery | Part of solvent can be recovery |

| Atomization structure | two-fluid |

| Atomization nozzle | 0.5/0.7/0.75/1.0/1.5/2.0 (mm) can be choose |

| Inert loop system | N2 closed loop system |

| Oxygen detection range | 0-100% (accuracy 0.1) |

| Oxygen detection module | Make sure oxygen concentration below 3% before starting to feed (value can be set) |

| Pressure measure range | 0-100Kpa |

| Explosion-proof module | Automatic pressure relief above 3Kpa (value can be set) |

| Explosion-proof membrane | automatic |

| Air volume adjustment | 0-30m³/h can be adjusted arbitrarily (inverter fan) |

| Drying tower size | φ20*H40 mm |

| Filter recovery size | φ17*H58 mm |

| Condensing unit size | φ17*H88 mm |

| Overall size | 770*585*1305 mm (W*D*H) |

| Total Power | 3.5 kw |

| Voltage/frequency | AC 220V/50Hz |