FD-300F-CE is a home commercial food freeze dryer is referred to as food freeze dryer, food lyophilizer, commercial lyophilization machine. The items processed by vacuum freeze drying are easy to be stored for a long time. After adding water, they can be restored to the state before freeze drying and maintain the original biochemical characteristics. It is suitable for heat sensitive substances such as antibiotics, vaccines, and blood products. enzymes, hormones and other biological tissues, freeze-drying technology is very suitable and widely used in medicine, pharmaceuticals, biological research, chemical industry, food and other fields.

Application of home commercial food freeze dryer

- Vegetables: Edible mushrooms, garlic slices, chives, green onions, green beans, peas, cucumbers, sweet corn kernels, diced carrots, spinach, asparagus, wild vegetables, etc.

- Aquatic products and meat: shellfish, shrimp, fish sticks, beef, pork, chicken, mutton slices, etc.

- Seasonings: garlic powder, ginger powder, green onion powder, tomatoes, pepper.

- Instant drinks: coffee, tea, soup, soy milk, milk, etc.

- Convenience food: children’s food, snack, camp food.

- Pharmaceutical field: Western medicine tablets, reagents, powdered injections, fresh Chinese herbal medicines, ginseng, deer antlers, wolfberry, Panax notoginseng, etc.

- Materials field: new graphene materials;

- Biological field: flowers, placenta, cells, etc.

SPECIFICATIONS of home commercial food freeze dryer

| Freeze drying chamber | |

| External material: | Carbon steel (stainless steel optional) |

| External shape: | box-type |

| Inner surface roughness: | Ra≤0.5 μm |

| door opening direction: | Clockwise opening (top view) |

| Freeze drying door: | organic glass |

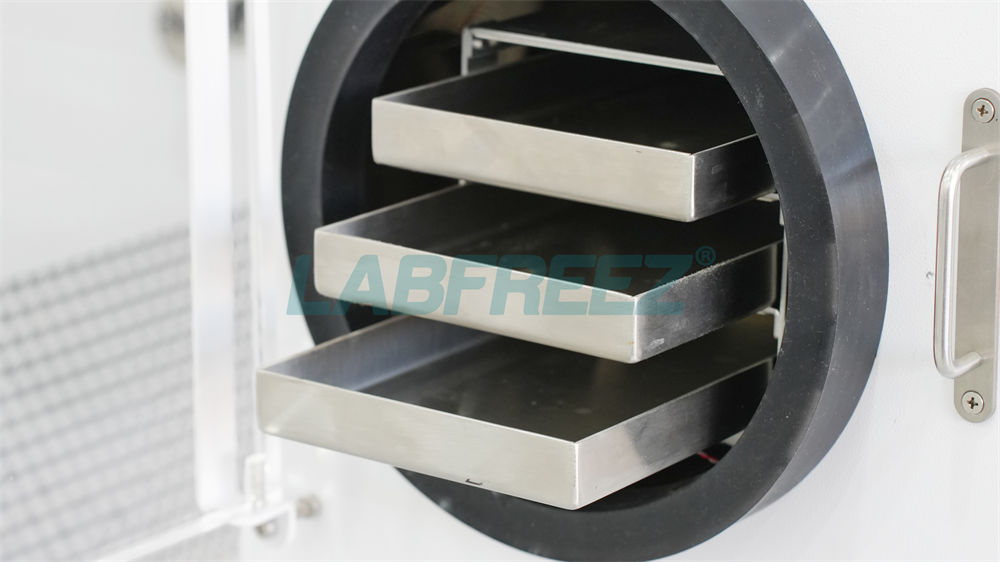

| Shelves components | |

| Shelf material: | Aluminum (stainless steel optional) |

| Layer structure form | Internal welding method with no solder joints on both upper and lower surfaces |

| Surface roughness: | Ra ≤ 0.5 μm |

| Flatness of board layer: | ≤± 0.5 mm / m2 |

| Layer spacing: | 45 mm |

| Material of material tray: | 304 stainless steel |

| Number of plate material trays: | 8 |

| Effective area of the board layer: | 3.0 m2 |

| ◆ Minimum temperature of the board layer: | ≤ -35 ℃ (no-load) |

| Cooling rate of the board layer: | ≤ 120 min (+20 ℃ to -35 ℃) |

| Board layer heating rate: | ≤ 20 min (-35 ℃ to+20 ℃) |

| Layer temperature difference: | ≤ ±1℃ |

| Layer temperature range: | -35℃ ~ +80℃ |

| Cold trap | |

| Cylinder material: | SUS 304 stainless steel |

| Cold trap form: | horizontal type |

| Cold trap door: | organic glass |

| Coil material: | copper tube |

| Surface roughness: | Ra ≤ 0.5 μm |

| Cold trap surface area: | ≤ 1.5 m2 |

| Ice condensation capacity: | ≤ 40Kg ★ Can be customized |

| Cooling rate of cold trap: | +Drop from 20 ℃ to -55 ℃/within 60 minutes |

| Minimum temperature of cold trap: | ≤ -55 ℃ (no-load) |

| Defrosting method: | Electric heating defrosting |

| Freezing system | |

|

|

| Compressor: | Globally leading Embraco brand, Imported fully enclosed piston compressor |

| ◆ Refrigerant: | Mixed refrigerant

★ Internationally recognized low-temperature, high-energy, and environmentally friendly refrigerants |

| Number of compressors: | 1 unit |

| Shelf cooling: | 1 unit (indirect cooling) |

| Cold trap refrigeration: | 1 unit (direct cooling) |

| Condenser: | Wind cooled |

| Refrigeration system protection | ★ Adopting products from internationally renowned brands, precise, stable, safe, and reliable. |

| Optional: | Cascade compressor

★ Cold trap temperature ≤ -80 ℃ |

| vacuum system | |

| Double stage rotary vane pump: | China high quality |

| quantity | 1 unit |

| System maximum vacuum: | ≤ 15 Pa |

| Evacuation rate of freeze-drying box: | Atmospheric pressure → 15 Pa < 5 minutes (under dry conditions) |

| System leakage rate: | ≤ 10 Pa·l / sec |

| ◆ Vacuum probe: | customized |

| Vacuum regulating valve | customized |

| Control System | |

| ◆ Control method: | Singlechip |

| ◆ Touch screen: | MCGS (Kunlun on state (7 inches) or Siemens |

| Intermediate relay: | Customized |

| Air circuit breaker: | Chint |

| Protect | |

| Whole machine startup protection: | The entire machine can only start running when all safety conditions of the equipment are met. |

| Operation protection: | The electrical system of the entire machine has logical interlocking, control, and protection functions. |

| Motor: | Equipped with overload, overheating, phase loss protection, etc |

| Circulating system: | Heating cycle protection |

| Product protection during sublimation process: | Cut off heating when the vacuum degree is poor |

| Cold trap protection for vacuum pump startup: | Interlock |

| Other parameters | |

| Power supply: | Single phase 220V |

| Installed power: | 4.5 KW |

| Overall structure: | Integrated freeze drying |

| Sheet Metal | 1.5mm steel plate |

| Painting | Imported famous brand environmentally friendly paint |

| Chassis and substrate | 5mm steel plate |

| temperature transmitter | Import famous brand |

| package | Plywood |