Pharmaceutical Freeze Dryer Lyophilizer, wall cross design, meet with GMPs standard, special design for process vials sample in clean room, 10~15kg(L)/day, Pre-freezing & drying in same chamber, is not only suitable for freeze-drying of bulk (liquid, paste, solid) conventional substances, but also suitable for drying of vials. When preparing for freeze-drying, the materials are divided into vials as needed, and the bottle caps are floated and then frozen. Drying. After drying, operate the capping device to tighten the bottle cap, which can avoid secondary pollution and re-adsorption of moisture, making it easy to store for a long time.

Features of Pharmaceutical Freeze Dryer Lyophilizer

Chamber

Rectangular type dry chamber, Pre-freezing, drying in same chamber without any manual operation.

- Drying chamber & shelves made by polished SS 304 or material contact parts SS316 is optional, adopted high strength, high transmittance plexiglass door, easy to observe, inside round corner, easy to clean.

- Roughness ≤6μm of inner wall of dry chamber an d shelves, flatness of shelves ≤ ±0.5mm / m to ensure best drying performance.

- Shelf temperature between -50°C to +70°C ±1°C (when it balance), Fast cooling from +20°C to -40°C within 60 min.

- Oil circulation heating type with high temperature precision control, usually suitable for medical, bio field, electric heating type suitable for food field.

- Shelves heating system uses safe voltage, while heating rate controllable, shelf made of mirror polish stainless steel, each shelf should be tested their roughness and flatness by professional tester in order to provide unifor mity temperature for sample.

- Wall-cross type is optional to meets with GMP standard.

Condenser (Cold Trap)

- Large capacity condenser design, made by SS304 material, SS316 is optional for the material which has high corrosivity.

- Lowest condenser temperature reach up to -86°Cfor silicone oil machine, -60°C for electric heating machine.

- Fast cooling from +20°C to -40°C within 30 min.

- Independent Cylinder-type cold trap, with high transmittance plexiglass door, powerful ice remove capacity to ensure best performance.

- Patented gas diversion technology, cold trapping ice even, ice-catching ability.

- Electric heating around the condenser chamber to remove ice effective.

Refrigeration System

- Dual-stage cooling technology easy to maintained.

- Famous brand hermetic compressor like Tecumseh (France brand) and DANFOSS (Sweden brand), low noise, and ensure powerful cooling performance.

- Danfoss brand of pressure controller and valve to ensure high stability.

- Condenser -86°Cfor silicone oil machine, -60°C for electric heating machine. fast cooling from +20°C to -40°C within 30 min.

- Shelf temperature between -50°C to +70°C ±1°C (when it balance), Fast cooling from +20°C to -40°C within 60 min.

- Air-cooled machine can be work in the room without additional cooling device.

- Used CFC-FREE environmental-friendly refrigerant.

- Brazed plate heat exchanger.

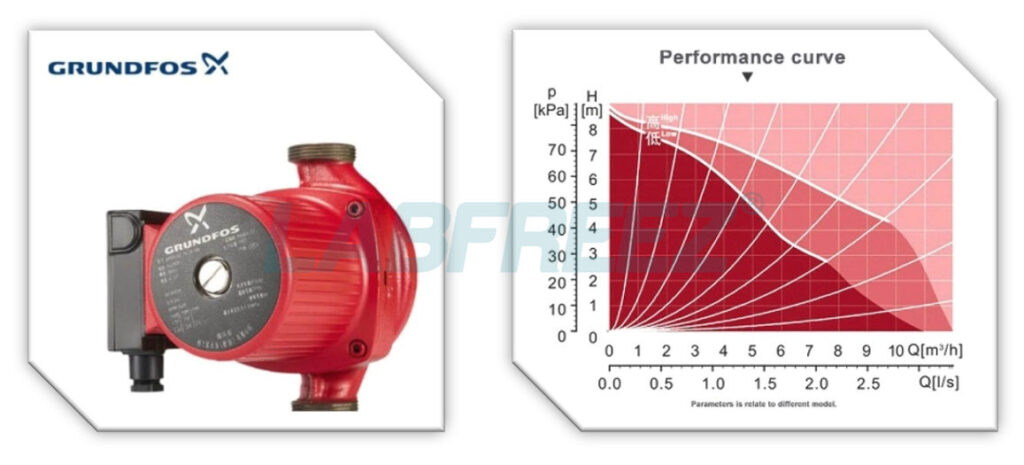

Circulation System

- GUNDFOS (Denmark brand) shielded circulating pump and PID control electric heating component; circulation liquid used Low-temperature low- viscosity silicone oil.

- Circulation system is for FD-10F-R, FD-20F, FD-30F-TP, FD-50F, FD-100F, FD-200F series.

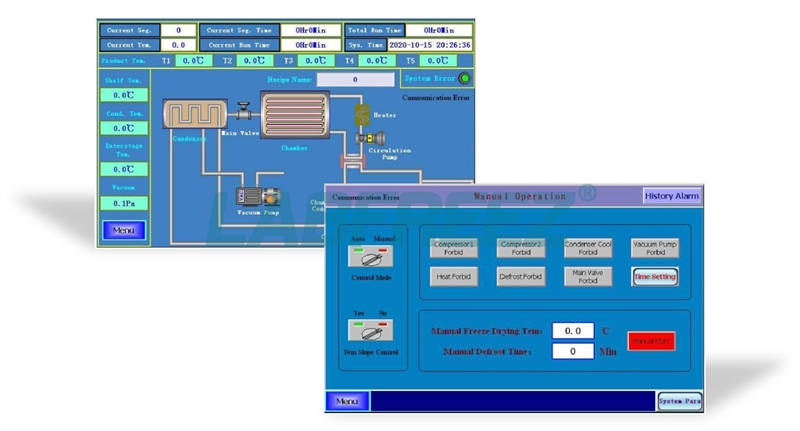

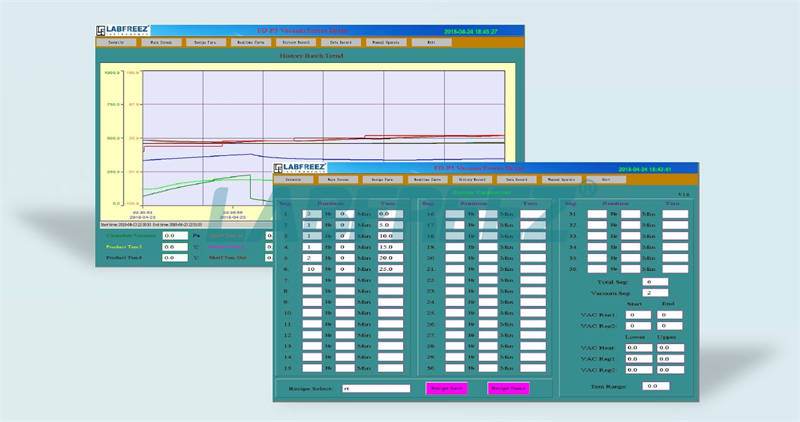

Control System

- Flexible manual + Auto control, manual groping process, auto batch production.

- PLC control with 7’ LCD touch graphic display, auto, semi-auto and manual mode available. (Siemens brand PLC + 10’’ touch screen is optional)

- Shelf temperature adjustable, controllable, explore suitable for pilot and production processes.

- 32 programs, each program can be set as 36 segments, curve can be stored, processing parameters can be modified in real time.

- Built with recorder, with USB interface data can be exported to computer for analysis, FD-LYO software & computer is optional for controlling by remote way.

- sensor calibration function, to ensure long-term use of the accuracy of the measured value.

- Real-time alarm display and historical alarm inquiry function, convenient fault diagnosis and equipment maintenance.

- Users can set the level and password, decentralized operation and management.

- WIFI Remote control software by computer or APP in mobile, you can set the machine in anywhere of the world. (Optional)

Vacuum System

- Two-stage rotary vane vacuum pump, vacuum is automatic adjust and can be set (optional).

- Ultimate vacuum can reach 1 Pa, in order to reach highest vacuum, LEYBOLD/ULVAC brand vacuum pump is optional.

- Pump performance from atmosphere to 10 Pa less than 30 min.

- System leaking rate less than 10 Pa·l / sec

Safety Protection

- Whole machine protection.

- Operation protection like electrical system have logic interlock, control and protection function.

- Alarm for vacuum system, heating system and etc.

- Power off/on protection, sublimation process protection

- Material protectionduring sublimation process, Heat cutting if vacuum lack

- Condenser-vacuum system interlock protection system.

Others

- Normal type suitable for bulk raw products like food, fruit, herbal medicine and bio material. Stoppering type suitable for vials comes with cap, to stoppering caps into the vials.

- Inflatable (water) valve with a safety diaphragm valve can be connected to the inert gas source, dry and filled with inert gas, to extend the shelf life of the material.

- CE/ISO 9001 13485 14001 certificated, can be conforms to GMP standard as per customer’s requirements

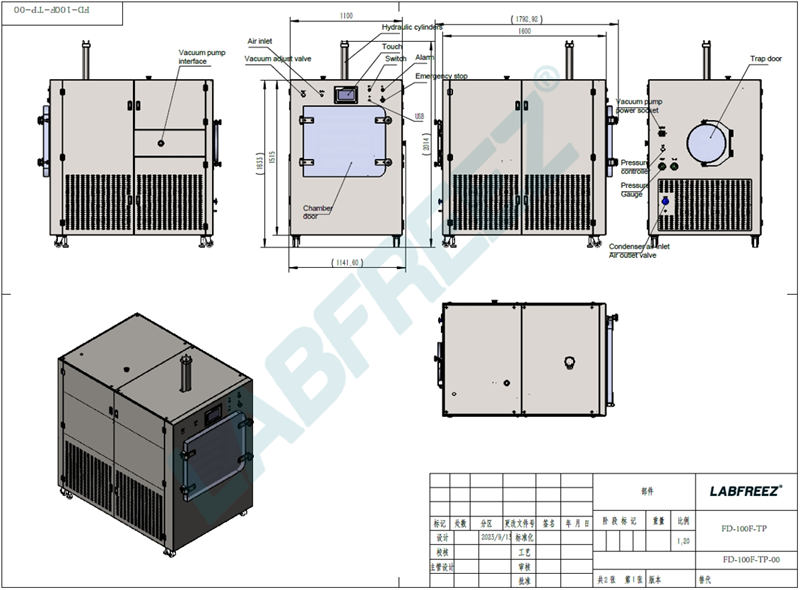

Specifications of Pharmaceutical Freeze Dryer Lyophilizer

| FD-100F Series | Model | FD-100F-TP Wall cross design |

| Heating type | Silicone oil circulation | |

| Picture |  |

|

| Drying chamber | Drying area | 1.15 m2 |

| Shelf quantity | 4+1 pcs | |

| Shelf Temp range | -50°C ~ +70°C | |

| Shelf temp. difference | ±1°C (balance) | |

| Shelves size | 480×600mm | |

| Tray size | 475×595mm | |

| Tray quantity | 4 pcs | |

| Raw material loaded capacity | 11L | |

| Height space | 70mm | |

| Material of chamber | Polish SS304 | |

| Material of Shelves | Polish SS304 | |

| Material of trays | SS304 | |

| Vials load capacity | Ф22 vials (PCS) | 2460 |

| Ф16 vials(PCS) | 4788 | |

| Ф12vials (PCS) | 8624 | |

| Cold trap | Condenser temp. | ≤-85°C |

| Ice Capture Capacity | 15 Kg/24h | |

| Condenser Size (D*L) | ||

| Defrost | Electric heating | |

| Material | SS304 | |

| Basic parameters | Vacuum pump | Included |

| Ultimate Vacuum | ≤1 Pa | |

| Pump rate | 15L/S | |

| Style of stoppering | Hydraulic pressure | |

| Cooling type | Air cooled | |

| Dimension (mm) | 1640×1105×1635+350 | |

| Voltage | 3p-380~400V/50Hz | |

| Install Power | 7500W | |

| Weight | 1000kg |