Modified plastics refer to plastic products that are modified on the basis of general-purpose plastics and engineering plastics through filling, blending, reinforcement and other methods to improve their flame retardancy, strength, impact resistance, toughness and other properties.

PA6 and PA66 (nylon 6 and nylon 66) are absolutely important varieties of engineering plastics. They have strong vitality. Secondly, they can achieve high performance after modification. Secondly, the automotive, electrical, telecommunications, electronics, machinery and other industries have increasingly strong requirements for high performance of products. The rapid development of related industries has promoted the process of high performance of engineering plastics, making it play an increasingly important role. Nylon is a crystalline polymer. The melting point is obvious and high. The melting point of PA6 is 215~225℃, and the melting point of PA66 is 250~270℃; therefore, nylon needs to be molded at a higher temperature. The thermal stability of nylon in the molten state is poor and easy to decompose. Therefore, the process conditions must be strictly controlled. From the appearance, the stability of modified plastics has little color difference. Differential scanning calorimetry can be used to distinguish whether it contains PA6 and PA66, as well as the ratio of these two materials.

1.DSC testing of PA6 and PA66 in engineering plastics

- Test material: Nylon (PA) material

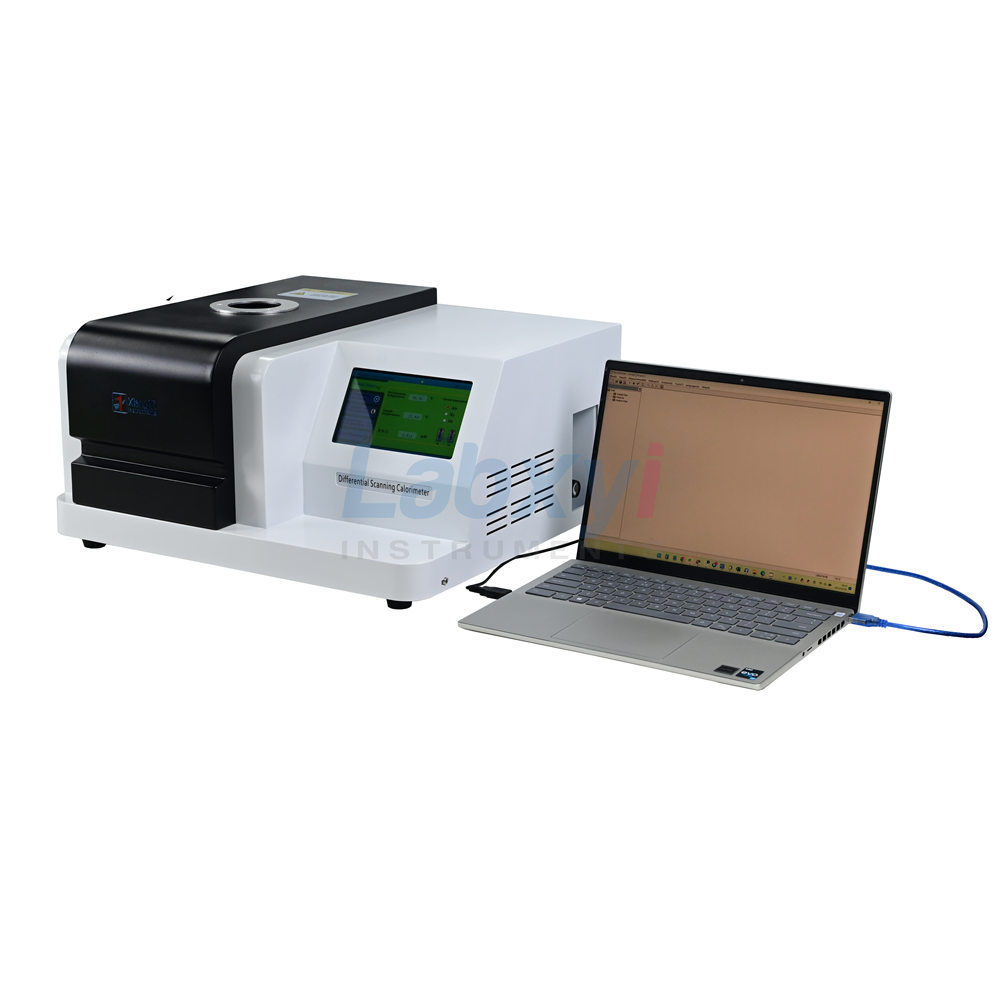

- Measuring instrument: DSC3000 differential scanning calorimeterTest principle:

- Differential scanning calorimetry is a technique that measures the heat flow difference between a substance and a reference substance and temperature or time under program temperature control and a certain flow atmosphere. The characteristic temperature and calorimetric characteristic parameters of the sample are obtained based on the analysis of the heat flow difference signal. Whenever the physical state of a material changes, such as melting, changing from one crystal form to another, or a chemical reaction occurs, it always absorbs or releases heat, and these changes often only require changing the temperature of the material to occur. DSC measures the relationship between the heat difference between the sample and the reference substance and the temperature under program temperature control.

2.Setting and selection of experimental parameters

The test instrument selected for this test is the high-precision DSC300 series model of Xiangyi Instruments Xiangtan Limited. Its advantage is that the sensitivity can reach 0.001℃, which can accurately and clearly test the differences in the content of different components of the sample. At the same time, it can be set in multiple temperature sections to achieve heating, constant temperature and cooling, PID intelligent temperature control, and two-way operation, which is more convenient and quick.

- Instrument selection

The test instrument selected for this test is the high-precision DSC300 series model of Xiangyi Instruments Xiangtan Limited. Its advantage is that the sensitivity can reach 0.001℃, which can accurately and clearly test the differences in the content of different components of the sample. At the same time, it can be set in multiple temperature sections to achieve heating, constant temperature and cooling, PID intelligent temperature control, and two-way operation, which is more convenient and quick.

- Test parameter requirements

2.1 Test parameter settings

Temperature: 300℃

Rate: 10℃/min

Atmosphere: N2, 50ml/min

.jpg)

2.2 There are three groups of samples tested, some of which are PA6, some are PA6 and PA66 mixtures, and some are added with other auxiliary materials; the differences of the products are tested by DSC3000 differential scanning calorimeter to control the quality of the products.

.jpg)

2.3 Each sample must be weighed before testing and then placed in the test crucible.

.jpg)

2.4 Test Spectrum Analysis

.jpg)

In the spectrum of sample 1, two endothermic peaks are seen, which are PA6 and PA66. The content of PA66 is slightly higher than that of PA6.

In the spectrum of sample 2, there is an endothermic peak near 158°C, which is due to the mixing of other plastics into the material; the other peak is the peak of PA66; the PA66 content is relatively high;

In the spectrum of sample 3, there are three peaks. There are two peaks near 210℃, which may be due to some differences in stability between the recycled material and the new PA6 material; the third peak is the peak of PA66;

The above data is tested by DSC3000 high-precision differential scanning calorimeter; if the accuracy is low, tiny change peaks may not be captured.