Rubber is a material that is currently widely used in all walks of life. Rubber has excellent properties such as high elasticity, viscoelasticity, cushioning and shock absorption, electrical insulation, softness and good waterproofness. It is mainly used in the automotive industry, construction industry, medical industry, electronics industry, etc. With the development of science and technology, the application field of rubber materials is also constantly expanding and innovating. However, in order to explore more applications of rubber, we must delve into the thermal properties of the material, study the composition of rubber and the product life. Among them, the commonly used methods for studying the thermal effect of rubber are DSC (differential scanning calorimeter) and TGA (thermogravimetric analysis).

The TGA method measurement is a process in which the sample mass changes continuously as the temperature rises. These changes can provide rich information on the stability of the material and its composition, and can detect the moisture, ash, and rubber content in rubber products. The different components in the rubber material are determined by the dynamic constant temperature rise method and the static constant temperature weight loss method of TGA. If the moisture or volatility test is carried out, the static constant temperature weight loss method can be used for quantitative detection, and the temperature is kept constant at a specified temperature to observe the specific weight loss. The dynamic constant temperature rise method is a commonly used TGA detection method. This method can simultaneously detect other components in the rubber, such as the content of the resist or ash.

Figure 1-1 Measuring instrument

- Rubber Research and Testing

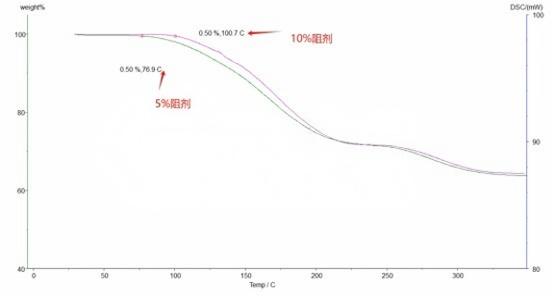

TGA can be used to evaluate the difference in weight loss under different additive contents of different product batches. As shown in the figure below (2-1), it can be seen that both batches of samples were heated to 350° under the same experimental conditions. When different amounts of additives were added when the weight loss was 0.5%, it was found that the temperature points of 0.5% weight loss were significantly different. The difference in the content of different additives is very obvious on the TGA curve. TGA detection technology can quickly detect the qualified rate of different batches, which is a very effective detection method.

Figure 2-1 Test spectrum of rubber sample

2. Static constant temperature weight loss method of rubber TGA

If other problems are found in the batch, the static constant temperature weight loss method can be used to detect and observe the situation. For example, when using TGA weight loss technology to determine the content of organic additives in the vulcanizer, the decomposition temperature of the organic additives and the rubber is relatively close. Through dynamic temperature increase testing, the weight loss peaks will be folded with each other, making it difficult to analyze the results. However, the weight loss state can be clearly observed through static constant temperature weight loss. By setting a temperature range through program-controlled temperature increase, and then analyzing and processing the TG curve in the temperature range again, it is possible to determine a temperature point where the organic additive will volatilize but the rubber will not volatilize. By continuously keeping the temperature constant at this temperature, the TG weight loss curve of the additive volatilization can be observed, that is, the weight loss content of the curve can be analyzed.