Polyethylene (PE) pipes have excellent chemical stability, are non-toxic, and are resistant to various chemicals such as hydrochloric acid, fluoric acid, phosphoric acid, formic acid, amines, potassium hydroxide, sodium hydroxide, etc. at room temperature. Polyethylene pipes are flexible, tough, light, and highly wear-resistant, and are widely used in various fields of life, such as petroleum, chemical industry, water supply, drainage, natural gas, etc.

Measurement Standards

Part 6 of GB/T19466 “Plastics Differential Scanning Calorimetry (DSC)”: Determination of oxidation induction time (isothermal OIT) and oxidation induction temperature (dynamic OIT).

Measuring instruments

- Instrument: DSC1000A Differential Scanning Calorimeter

- Gas: nitrogen, oxygen

- Test sample: PE pipe material

Experimental parameters

- Sample weight: 10±3mg

- Gas flow rate: 50±10ml

- Heating rate: 20℃/min

- Cut-off temperature: 200℃

Experimental operation

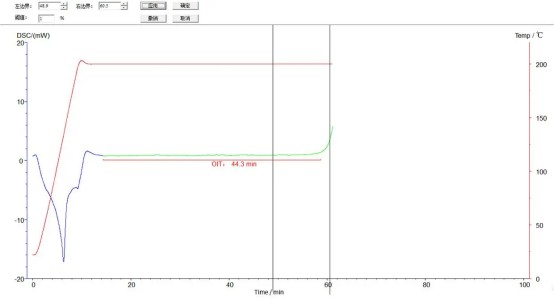

Trim and weigh the sample to about 10 mg, then place it in an aluminum crucible, take another aluminum crucible for comparison, and then place the two crucibles in the furnace of the instrument. Cover the lids one by one. Raise the temperature to 200° under the protection of a nitrogen atmosphere and keep the temperature constant for 5 minutes. After 5 minutes of constant temperature, immediately switch to oxygen, and then measure the time required for the sample to reach the oxidation induction temperature point and decompose under the condition of oxygen gas. This time is the oxidation induction time of PE plastic, i.e. OIT. The following figure shows the software settings and OIT results:

Spectral analysis

From the above curve, we know that the curve of the PE material extends upward at about 44 minutes, and an exothermic reaction occurs, that is, an oxidation reaction occurs on the surface of the sample, so the oxidation induction time of the sample is 44.3 minutes.

Note: The higher the experimental cut-off temperature, the shorter the OIT time; the faster the temperature rises, the higher the oxidation induction temperature.

Experimental Notes

- Different sample surface area to volume ratios, poor sample uniformity, residual stress, and poor contact between the sample and the sample dish can all have an adverse effect on the accuracy of the test results.

- Accurate temperature control and pure gas atmosphere can eliminate the influence of non-material factors on the results, which is very important for the measurement of oxidation induction period.

- The OIT time should be compared according to the unified standard. Different standards are not comparable.

Instrument advantages

- The new furnace structure enables the instrument to have better baseline stability during operation, thus ensuring the accuracy and reliability of the test results.

- Two-way control interface: DSC1000A supports two-way control (host control and software control), making operation more convenient.

- Alloy sensor: DSC1000A uses a professional alloy sensor, which has strong corrosion and oxidation resistance. It can maintain high performance and long-term stability even in harsh experimental environments, ensuring the accuracy and reliability of experimental data.

- Software analysis. The matching analysis software can collect measurement graphs in real time, perform online data analysis, and has the function of saving data.

- One-key calibration function. Equipped with a one-key calibration function for standard substances, users can calibrate temperature and enthalpy by themselves. This flexibility greatly facilitates user use and maintenance, while also ensuring the accuracy and consistency of test results.