CTA-1000A Automatic Reaction Calorimeter is a professional test instrument that simulates the specific process of chemical reactions on a liter scale, measures and controls important process variables. It can simulate the actual situation of batch or semi-batch reactions in factories under laboratory conditions.

Features

1) It has three calorimetric methods: heat flow, power compensation, and reflow. Users can choose according to their needs.

2) Support multiple operation modes such as isothermal, constant temperature, scanning, etc.

3) Glass atmospheric pressure reactor, glass medium pressure reactor, metal high pressure reactor are optional

4) With peripheral database, one system supports multiple reactors interchangeable

5) High-power heating and cooling units, fast temperature control response speed, and high heat release measurement accuracy

6) Automatic feeding control, which can be measured by mass or volume

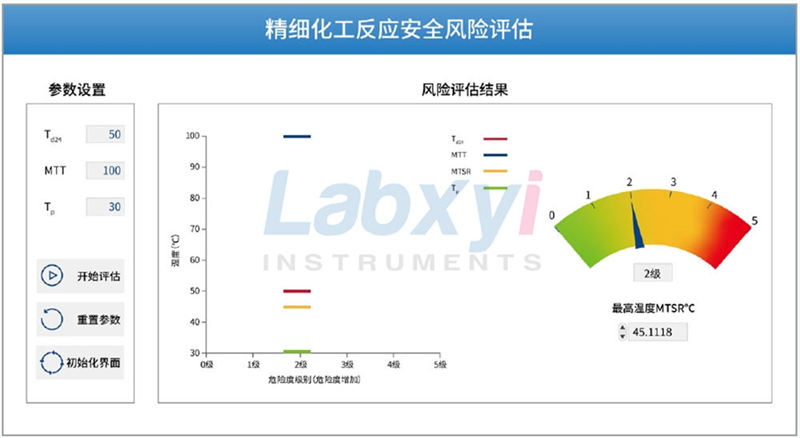

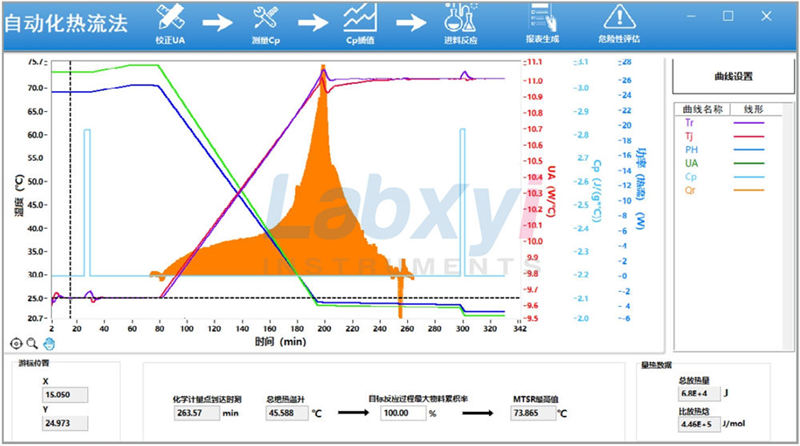

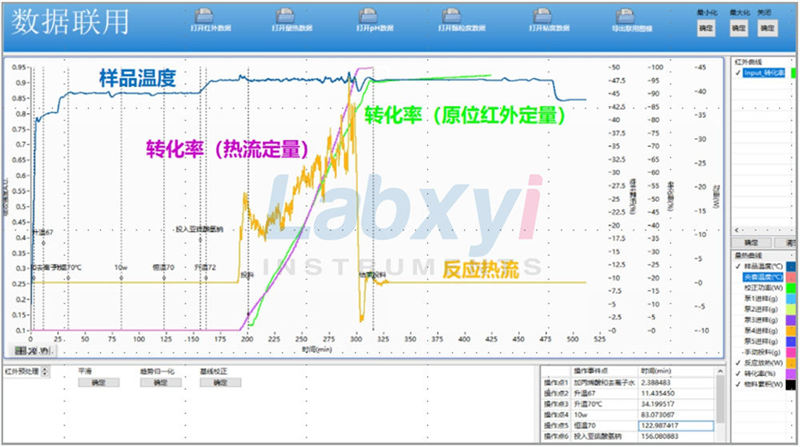

7) Accurately measure and obtain process safety related data such as reaction heat flow, reaction enthalpy, conversion rate, sample specific heat capacity, adiabatic temperature rise, and the maximum temperature that the out-of-control system can reach.

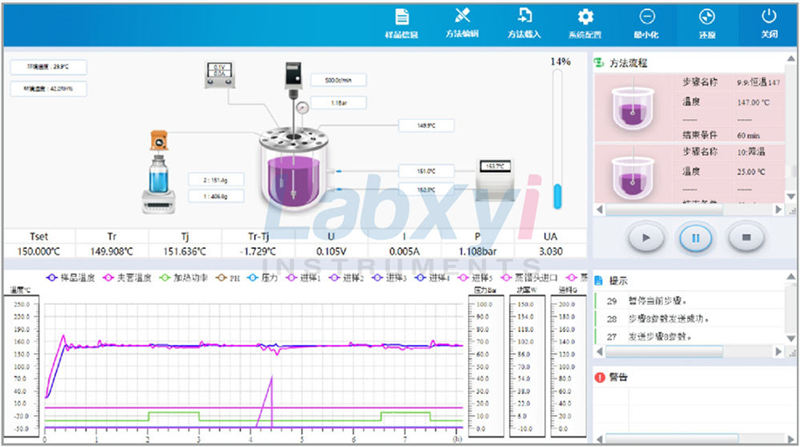

8) The English software platform can flexibly compile experimental processes, monitor key data of the reaction process in real time, and modify experimental processes and parameters online

9) Real-time display of test status such as kettle temperature, jacket temperature, feed quality, etc.

10) Key parameters and status safety thresholds can be set. When the reaction is out of control, “one-click” rapid cooling, abnormal state alarm and automatic shutdown can be performed to effectively ensure safety

11) Automatically generate and save charts and data, and export experimental analysis reports

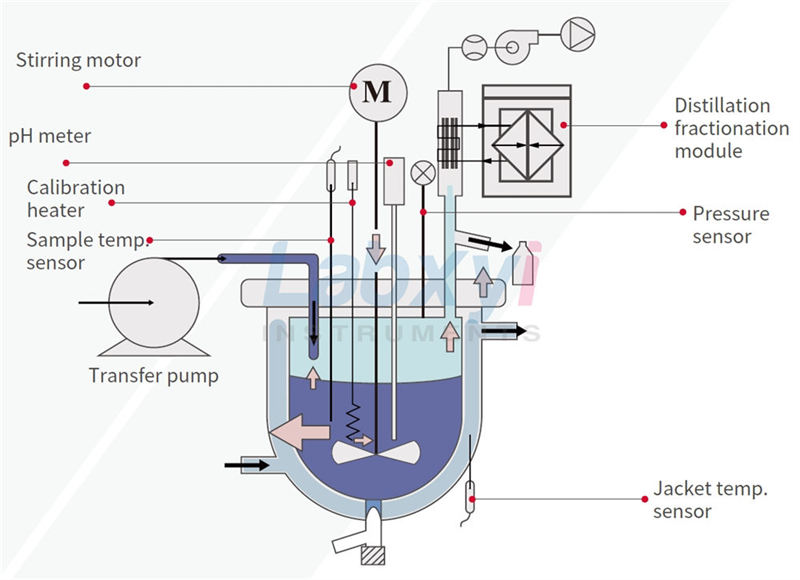

About Structure

About mode

1) Heat flow method

Heat flow calorimetry can accurately determine the specific heat capacity of the sample and the heat transfer factor between the sample and the reactor jacket through a calibration process, and measure the temperature difference between the sample and the jacket in real time during the reaction process, and calculate the real-time heat release heat flow of the sample. The heat flow method can obtain more accurate calorimetric data.

2) Power compensation method

Power compensation calorimetry uses a calibrated heater to provide a certain background power to maintain the entire system in thermal equilibrium. During the reaction, the real-time heat release heat flow of the sample is calculated by measuring the change in heater power. The power compensation method can be used to conduct experiments more efficiently.

3) Distillation Reflux

Reflux (distillation) calorimetry can determine the specific heat capacity of the sample, the heat transfer factor between the condenser and the refrigerant, and between the sample and the reactor jacket through the calibration process, and measure the temperature difference between the inlet and outlet of the condenser and between the sample and the jacket in real time during the reaction process, and calculate the real-time heat release heat flow of the sample. When the reaction is carried out under boiling conditions, the reflux mode calorimetry is required.

Technical specifications

| MODEL | CTA-1000A |

| Calorimetric method | Heat flow method, power compensation method (optional), reflow method (optional) |

| temperature control | |

| Kettle body temperature range | (-25~200)℃ |

| Oil bath temperature range | (-45~250)℃ |

| control method | Isothermal, Constant Temperature, Scanning |

| Temperature resolution | 1.0mK |

| Temperature control precision | ±0.1K |

| Silicone oil circulation speed | (35~76)L/min |

| Power Control | |

| Driver voltage range | (0~50)VDC |

| Driver maximum current | 3.0A |

| Heater maximum power | 120W |

| Atmospheric pressure glass reactor (optional) | |

| Reactor volume | 1000mL, other volumes can be customized |

| Work Pressure | Atmospheric pressure |

| Reactor material | Glass |

| Medium pressure glass reactor (optional) | |

| Reactor volume | 1000mL, other volumes can be customized |

| Work Pressure | 0.6MPa or 1.2MPa |

| Reactor material | Glass |

| Reactor cover material | 316L stainless steel or Hastelloy |

| High pressure metal reactor (optional) | |

| Reactor volume | 1000mL, other volumes can be customized |

| Work Pressure | 10MPa |

| Reactor material | 316L stainless steel or Hastelloy |

| Mixer | |

| Maximum speed | 2000r/min, 3000r/min optional |

| Maximum Torque | 75N·cm, optional 300N·cm |

| Stirring paddle type | Anchor or paddle |

| Material of stirring paddle | PTFE, 316L or Hastelloy |

| Injection system | |

| Precision balance | Range 3100g, accuracy 0.01g |

| Injection channel | 1 liquid inlet, 1 solid inlet, 1 gas inlet; the number of inlets can be expanded to 4 |

| Injection pump | Medium pressure pump: electromagnetic diaphragm pump, maximum flow rate 2L/h; high pressure pump: precision plunger pump, maximum flow rate 2.4L/h |

| Other parameters | |

| power supply | 3*400V/50 Hz( ±10%)/20A |

| power | 7000VA |

| Test area size | 1200*600*1855mm |

| Oil bath size | 600*700*1305mm |

| Oil bath weight | 210kg |

| Total Weight | 300kg |