Food Home freeze dryer is referred to as food freeze dryer. The items processed by vacuum freeze drying are easy to be stored for a long time. After adding water, they can be restored to the state before freeze drying and maintain the original biochemical characteristics. It is suitable for heat sensitive substances such as antibiotics, vaccines, and blood products. enzymes, hormones and other biological tissues, freeze-drying technology is very suitable and widely used in medicine, pharmaceuticals, biological research, chemical industry, food and other fields.

Features of small food home freeze dryer

- The whole machine has humanized design, plug and play, beautiful appearance, compact structure and high cost performance.

- The box-trap integrated design has a shorter sublimation channel, which is conducive to the rapid sublimation of large amounts of water vapor.

- Original imported refrigeration compressor, with large cooling capacity, high efficiency and energy saving, long service life and low noise.

- Using aerospace-grade high-transmittance plexiglass door, the entire process of sample freeze-drying changes can be observed in real time.

- Easy to operate and highly automated, the entire freeze-drying process can be completed with just one button.

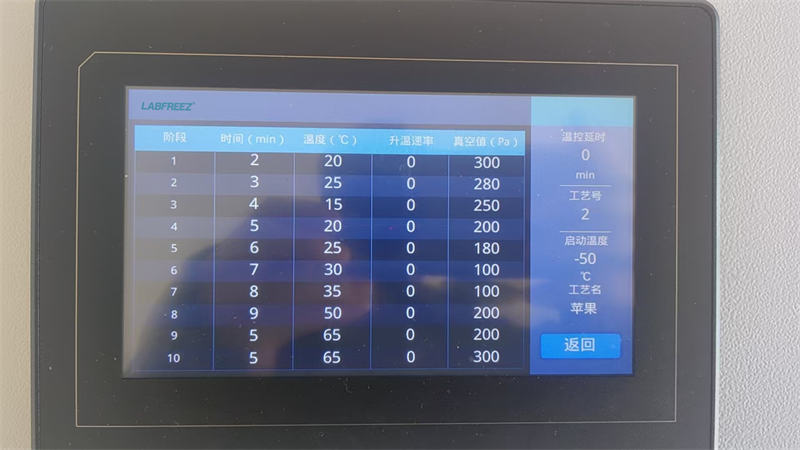

- The standard freeze-drying process is preset, so there is no need to have an in-depth understanding of cumbersome freeze-drying principles &freeze-drying processes, and process can be imported with one click.

- Intelligent fault diagnosis technology displays fault information in text form, which greatly facilitates equipment maintenance and fault repair.

- Safety lock function. Prevent incorrect operations from modifying the system status and process parameters, causing freeze-drying failure or instrument damage.

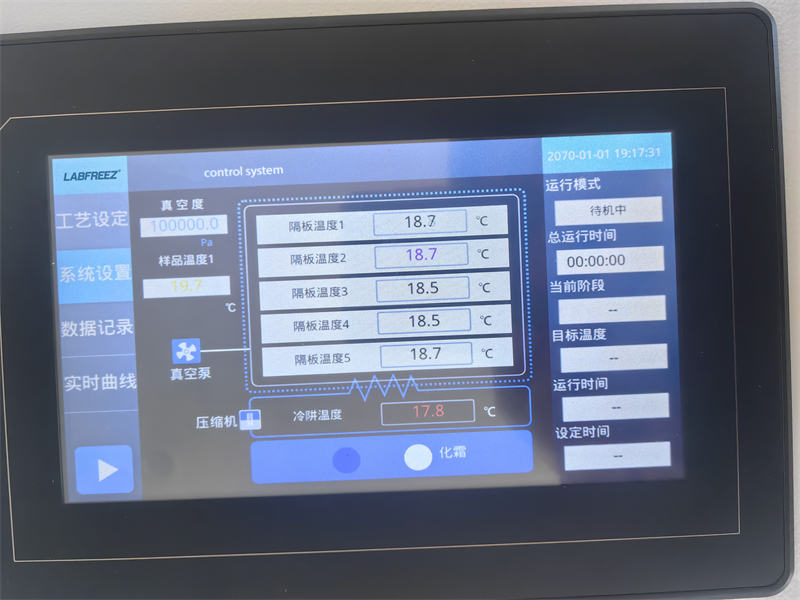

- The intelligent energy-saving temperature control technology of the partition has high temperature control accuracy, significant energy-saving effect, and the system is stable and reliable.

- One-click rapid defrosting technology, safe and efficient.

Application of food home freeze dryers

- Vegetables: Edible mushrooms, garlic slices, chives, green onions, green beans, peas, cucumbers, sweet corn kernels, diced carrots, spinach, asparagus, wild vegetables, etc.

- Aquatic products and meat: shellfish, shrimp, fish sticks, beef, pork, chicken, mutton slices, etc.

- Seasonings: garlic powder, ginger powder, green onion powder, tomatoes, pepper.

- Instant drinks: coffee, tea, soup, soy milk, milk, etc.

- Convenience food: children’s food, snack, camp food.

- Pharmaceutical field: Western medicine tablets, reagents, powdered injections, fresh Chinese herbal medicines, ginseng, deer antlers, wolfberry, Panax notoginseng, etc.

- Materials field: new graphene materials;

- Biological field: flowers, placenta, cells, etc.

SPECIFICATIONS of home freeze dryer

| MODEL | FD-10F-CE | FD-30F-CE | FD-40F-CE | FD-60F-CE | FD-100F-CE |

| Picture |  |

|

|

|

|

| Shelf | |||||

| Shelf area | 0.1 m2 | 0.4 m2 | 0.43 m2 | 0.67 m2 | 1.0 m2 |

| Shelf temperature range | -20 ~ +70°C(no load) | -20 ~ +70°C(no load) | -20 ~ +70°C(no load) | -20 ~ +70°C(no load) | -20 ~ +70°C(no load) |

| Shelf Flatness | ≤ ±1.0mm / m | ≤ ±1.0mm / m | ≤ ±1.0mm / m | ≤ ±1.0mm / m | ≤ ±1.0mm / m |

| Shelf material | Aviation aluminum | Aviation aluminum | Aviation aluminum | Aviation aluminum | Aviation aluminum |

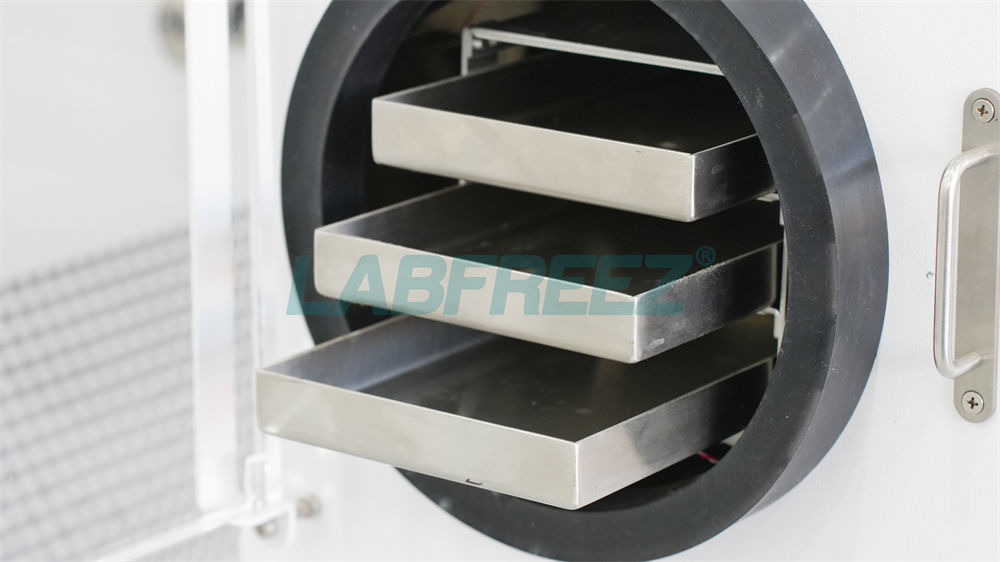

| Number of shelf | 3+1 | 4+1 | 5+1 | 5+1 | 4+1 |

| Shelf spacing | 40mm | 40mm | 40mm | 40mm | 50mm |

| Temperature heating rate | -20°C to +20°C within 60m | -20°C to +20°C within 60m | -20°C to +20°C within 60m | -20°C to +20°C within 60m | -20°C to +20°C within 60m |

| Number of trays | 3 pcs | 4 pcs | 5 pcs | 5 pcs | 4 pcs |

| Material processing capacity | 1-1.5L | 4-5L | 4-5L | 6-7L | 10-15L |

| Trays material | ANSI SS304 | ANSI SS304 | ANSI SS304 | ANSI SS304 | ANSI SS304 |

| Condenser | |||||

| Condenser temperature | ≤-45°C (no load) | ≤-45°C (no load) | ≤-45°C (no load) | ≤-45°C (no load) | ≤-56°C (no load) |

| Condenser cooling rate | +20°C~40°C within 30m | +20°C~40°C within 30m | +20°C~40°C within 30m | +20°C~40°C within 30m | +20°C~40°C within 30m |

| Condenser defrost | Electric defrost | Electric defrost | Electric defrost | Electric defrost | Electric defrost |

| Water catching capacity | ≥2Kg/24h | ≥4Kg/24h | ≥6Kg/24h | ≥10Kg/24h | ≥10Kg/24h |

| Chamber | |||||

| Chamber material | AISI 304 SS | AISI 304 SS | AISI 304 SS | AISI 304 SS | AISI 304 SS |

| Chamber door material | ACRYLIC | ACRYLIC | ACRYLIC | ACRYLIC | ACRYLIC |

| thermal insulation material | Polyurethane foam | Polyurethane foam | Polyurethane foam | Polyurethane foam | Polyurethane foam |

| Roughness of inner wall | Ra ≤ 1.0 um | Ra ≤ 1.0 um | Ra ≤ 1.0 um | Ra ≤ 1.0 um | Ra ≤ 1.0 um |

| Coiling pipe material | AISI 304 | AISI 304 | AISI 304 | AISI 304 | AISI 304 |

| refrigeration system | |||||

| Compressor type | Full closure compressor | Full closure compressor | Full closure compressor | Full closure compressor | Full closure compressor |

| Compressor brand | International famous brand | International famous brand | International famous brand | International famous brand | International famous brand |

| Compressor number | 1 set | 1 set | 1 set | 1 set | 1 set |

| Refrigerant | CFC-FREE | CFC-FREE | CFC-FREE | CFC-FREE | CFC-FREE |

| Vacuum System | |||||

| Evacuation rate | 2L/S | 2L/S | 2L/S | 4L/S | 4L/S |

| Ultimate vacuum | ≤5 Pa (no load) | ≤5 Pa (no load) | ≤5 Pa (no load) | ≤5 Pa (no load) | ≤5 Pa (no load) |

| Pump type | Double stage rotary vane pump | Double stage rotary vane pump | Double stage rotary vane pump | Double stage rotary vane pump | Double stage rotary vane pump |

| Pump number | 1 set | 1 set | 1 set | 1 set | 1 set |

| Vacuum gauge | Reborn | Reborn | Reborn | Reborn | Reborn |

| System leaking rate | ≤ 10 Pa·l / s | ≤ 10 Pa·l / s | ≤ 10 Pa·l / s | ≤ 10 Pa·l / s | ≤ 10 Pa·l / s |

| CONTROL SYSTEM | |||||

| Control style | Automatic & Manual | Automatic & Manual | Automatic & Manual | Automatic & Manual | Automatic & Manual |

| Screen | 5’’ color touch | 5’’ color touch | 7’’ color touch | 7’’ color touch | 7’’ color touch |

| Main function | Manual + Auto Control Mode, Sensor calibration, Intelligent temperature control, Freeze drying termination reminding and other functions are available. | ||||

| Machine power supply | AC220V, 50Hz | AC220V, 50Hz | AC220V, 50Hz | AC220V, 50Hz | AC220V, 50Hz |

| Machine power | 1kW | 2kW | 2kW | 2.5kw | 3.5kw |

| Cooling method | Air cooled | Air cooled | Air cooled | Air cooled | Air cooled |

| Host weight | 40Kg | 80Kg | 80Kg | 120kg | 200kg |

| Safety protection | |

| Whole machine protection | All safety conditions are ready for whole machine, machine can start running. |

| Operation protection | Electrical system has logic interlock, control and protection functions. |

| Vacuum pressure | Available |

| Power cut and supply | With safety protection measure |

| Products protection during sublimation process | Heat cutting if vacuum lack |

| Condenser protection when vacuum pump start | Interlock |