FD-PE series universal vacuum freeze drying machine is suitable for the drying of high-grade raw material medicines, Traditional herbal medicines, biological, wild vegetables, dehydrated vegetables, food, fruits, chemicals, pharmaceutical intermediates and other materials.

Advantages

- The separator is made with unique patented technology, high pressure resistance, high flatness, and good temperature uniformity.

- Highly efficient mixed refrigerant medium, lower freezing point and higher boiling point, high heat exchange efficiency.

- The drying curve optimization control algorithm can control the heating rate and vacuum value of the product in the drying stage.

- The patented gas diversion design and control technology has strong water catching ability and high drying efficiency.

- Vacuum adjustment during drying operation to avoid foaming and blowing of special materials and improve drying efficiency.

- Industrial-grade embedded touch screen + dedicated LF-HPSC-IV modular controller, stable and reliable system, high control accuracy.

- The professionally designed LYO-CONTROL control system can save multiple sets of process recipes. At the same time, the process can be adjusted in real time during the drying process to improve the process optimization rate.

- Flexible manual + automatic control mode, manual use for groping process, automatic batch production.

- You can set user level and password, and decentralize operations and management.

- Optional powerful LYO-MEGA host computer control system can record, save up to ten years of operating data, curves and alarm records, improve product traceability; at the same time convenient observation, operation and fault diagnosis.

- Can be customized according to user needs.

MAIN FEATURES

-300x269.jpg) |

Excellent materials and machining ·Quality materials for whole machine, SS304 external & internal ·Polish SS304 of shelves & chamber, Condenser & sample trays made of SS304. ·Door material polish SS304 with observe window, door open direction can be Clockwise or anticlockwise ·AISI 316 material is optional for material contact part ·Precision machining and welding technology, system leaking rate ≤ 10 Pa·l / sec ·Strict standards FAT testing in factory to ensure worry-free system delivery

|

|

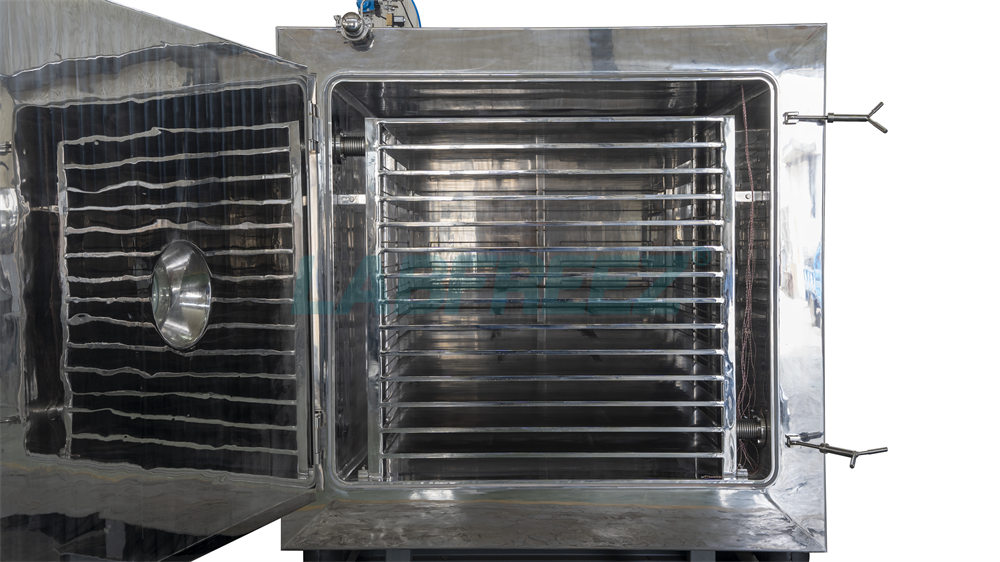

GMP standard shelf

· AISI 304 Top and bottom plate thickness 5mm ·Roughness Ra ≤ 0.4 μm, Flatness ≤ ±0.5mm / m · Temperature decreasing rate +20°C down to -40°C/ within 60 min (no load testing) · Temperature elevating rate -40°C up to +20°C/ within 60 min · Temperature lowest ≤ -50°C, highest≥ +80°C, accuracy ≤ ±1°C (in balance)

|

|

|

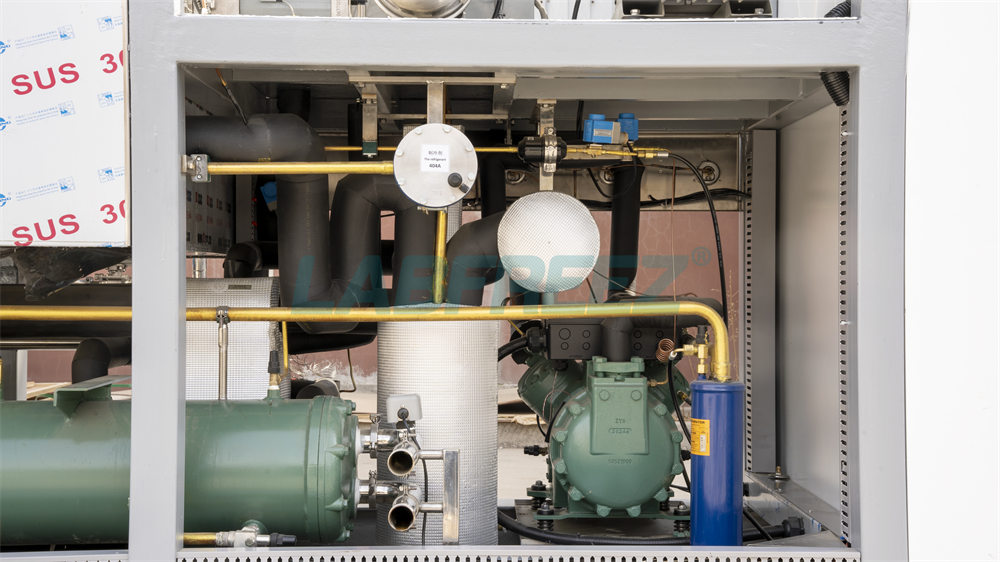

Germany brand refrigeration system

·Original imported from Germany Bitzer brand · To ensure high accuracy and stable performance ·Dual cascade refrigeration system, easy maintenance ·Used CFC-FREE green refrigerant gas ·Lowest temperature up to -85°C, 20°C cooling to -40°C within 60 min ·Long-term life time

|

|

|

Denmark Liquid circulation temperature control system

·Denmark GRUNDFOS brand web rotor canned circulation pump ensure high accuracy on shelf temperature control ·Low viscosity silicon oil as thermal exchange media which make temperature more stable, accuracy ·AISI SS304 material circulation pipe, PT-100 platinum resistance temperature sensor

|

|

|

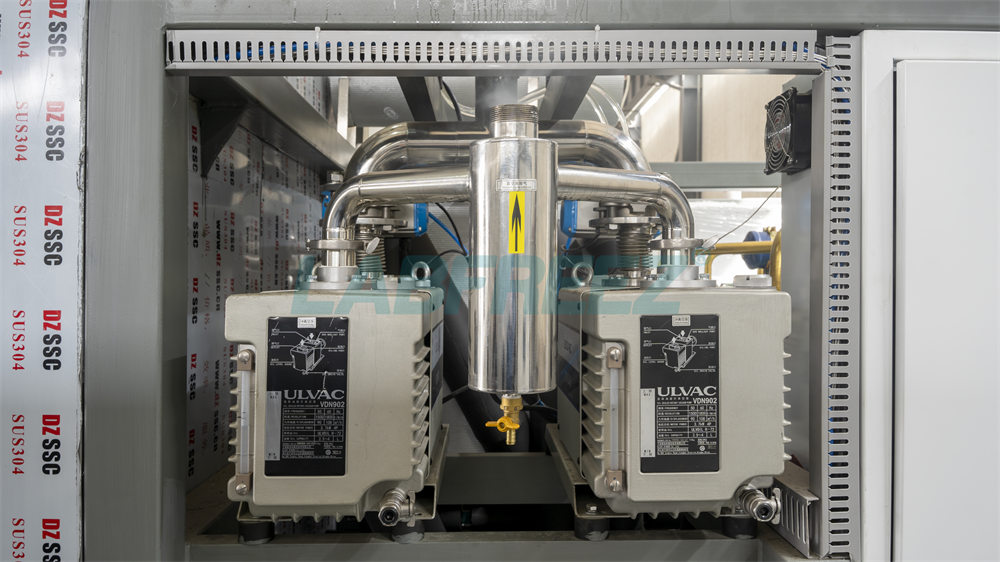

germany brand vacuum system

· Germany Leybold double stage rotary vane pump · System final vacuum up to 1 Pa (empty) ·Atmosphere ~ 10 Pa ≤30 minutes (in dry condition) ·Vacuum degree can be adjustable (optional) · England Edwards vacuum pump is optional

|

|

Auto + manual Control system

· FATEK PLC control · SCADA system; user, recipe, and test data can be manager · WIFI remote computer control system is available to ensure system be controlled in remote · Can be stored 32 groups freeze-dried process data; · Each group can be set up to 36 segments · Built recorder system, data can be search, print and export to computer

|

|

Safety protection system

· Electrical system has logic interlock, control and protection function · Motor overload, overheat, lack of phase · Audible and visual warnings for Refrigeration system, Vacuum pressure, Heating system, Circulation system, Water shortage, air shortage · Power cut protection when breakdown · Condenser protection when vacuum pump start · Vacuum pump stopping, pump valve automatically closed · Heat cutting if vacuum lack · Defrosting interlock protection

|

|

Specifications

| MODEL | FD-P1E | FD-P2E | FD-P3E | FD-P5E | FD-P10E | FD-P15E |

| Shelf area | 1.15 | 2.16 | 3.24 | 5.2 | 10.5 | 15 |

| Material load capacity (10mm, L) | 10 | 20 | 30 | 50 | 100 | 150 |

| Shelf quantity (pcs) | 4+1 | 4+1 | 6+1 | 7+1 | 7+1 | 10+1 |

| Shelf size (mm) | 480*600 | 600*900 | 600*900 | 750*1000 | 990*1520 | 1520*990 |

| Shelf high space (mm) | 80 | 80 | 80 | 80 | 80 | 80 |

| Shelf temp. range (°C) | -50 ~ +80 | -50 ~ +80 | -50 ~ +80 | -50 ~ +80 | -50 ~ +80 | -50 ~ +80 |

| Ice capture capacity (kg/batch) | ≥20 | ≥40 | ≥60 | ≥100 | ≥200 | ≥300 |

| Condenser temperature (°C) | ≤-75°C | ≤-75°C | ≤-75°C | ≤-75°C | ≤-75°C | ≤-75°C |

| Machine Cooling method | Water-cooled | Water-cooled | Water-cooled | Water-cooled | Water-cooled | Water-cooled |

| Defrost way | Water soak | Water soak | Water soak | Water soak | Water soak | Water soak |

| Ultimate Vacuum (Pa) | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 |

| Total power (KW) | 15 | 18 | 21 | 23.5 | 50 | 75 |

| Dimensions (cm) | 250*110*200 | 250*130*200 | 280*120*250 | 400*150*250 | 500*210*360 | 650*230*360 |

| Weight (kg) | 1200 | 2000 | 2800 | 3500 | 6500 | 8000 |

| MODEL | FD-P20E | FD-P30E | FD-P40E | FD-P50E | FD-P60E |

| Shelf area | 20.2 | 29.7 | 40.5 | 51 | 60 |

| Material load capacity (10mm, L) | 200 | 300 | 400 | 500 | 600 |

| Shelf quantity (pcs) | 11+1 | 11+1 | 15+1 | 17+1 | 20+1 |

| Shelf size (mm) | 1210*1520 | 1500*1800 | 1500*1800 | 1500*2000 | 1500*2000 |

| Shelf high space (mm) | 80 | 80 | 80 | 80 | 60 |

| Shelf temp. range (°C) | -50 ~ +80 | -50 ~ +80 | -50 ~ +80 | -50 ~ +80 | -50 ~ +80 |

| Ice capture capacity (kg/batch) | ≥400 | ≥600 | ≥800 | ≥1000 | ≥1200 |

| Condenser temperature (°C) | ≤-75°C | ≤-75°C | ≤-75°C | ≤-75°C | ≤-75°C |

| Machine Cooling method | Water-cooled | Water-cooled | Water-cooled | Water-cooled | Water-cooled |

| Defrost way | Water soak | Water soak | Water soak | Water soak | Water soak |

| Ultimate Vacuum | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 |

| Total power (KW) | 93 | 130 | 185 | 210 | 210 |

| Dimensions (cm) | 650*230*360 | 740*230*380 | 920*240*400 | 940*240*450 | 900*240*450 |

| Weight (kg) | 9500 | 15000 | 20000 | 30000 | 30000 |

Documents

| Item NO. | DESCRIPTION |

| 1 | FAT testing report |

| 2 | Operation Manual + Packing list |

| 3 | GMP 3Q IQ + OQ + PQ |

| 4 | Floorplan |

| 5 | P&ID |

| 6 | Electrical circuit diagram |

| 7 | ISO 9001 & 14001 certificate |

| 8 | CE certificate |

| 9 | Material certificate |

Optional list

| Item NO. | Description |

| FDPEO010 | CIP system |

| FDPEO011 | SIP system |

| FDPEO012 | High level vacuum control |

| FDPEO013 | Remote control system with computer |

| FDPEO014 | Remote control system by mobile application (IOS/Android) |

| FDPEO015 | High level vacuum pump |

| FDPEO016 | AISI SS316 for sample contact part |

| FDPEO017 | Extra set of trays |

| FDPEO018 | Machine design suit for clean room |

| FDPEO019 | Eutectic point tester |

| FDPEO020 | Chamber condenser isolation valve |

| FDPEO021 | Pneumatic door opening |

Brand of main accessories