1.Introduction

Differential scanning calorimeters are increasingly being used. This test case is the application of differential scanning calorimeters in the field of fiber and textile engineering. Polyester fiber is a widely used synthetic fiber currently. It is a synthetic fiber obtained by spinning from organic dibasic acids and dibasic concentrates. At present, polyester fibers mainly include polybutylene terephthalate (PBT) and polybutylene terephthalate (PTT). Using DSC differential scanning calorimeter, the thermal properties of polybutylene terephthalate (PBT) were tested. The heating rate was determined by studying the changes in the thermal properties of PBT at different heating rates, studying the linear relationship between the mass and thermal enthalpy of PET, and determining a quantitative analysis method for PBT materials in DSC equipment. At the same time, the composition, structure and properties of fabric materials were studied in depth through differential scanning calorimeters, providing important technical support for the development and application of textiles.

2.Experimental Operation

2.1 Instruments and experimental conditions

Equipment: Differential Scanning Calorimeter DSC1000A (Xiangyi Instruments Xiangtan Limited)

Gas: Nitrogen atmosphere flow rate is 50ML/min

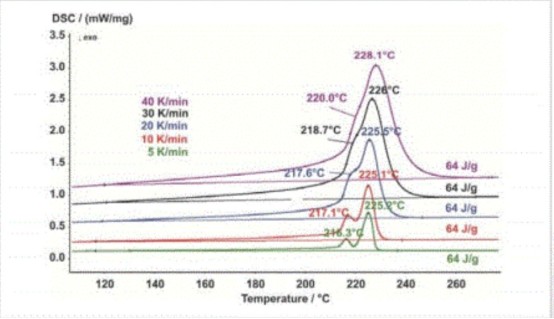

Experimental conditions: 5k/min, 10k/min, 20k/min, 30k/min, 40k/min tests were performed respectively. The temperature was raised to 300°.

2.2 Test situation

The figure below shows the basic test results of different heating rates on the melting process of PBT. It can be seen that the faster the heating rate, the wider the peak of the DSC curve. We found that at a heating rate of 40k/min, the thermal enthalpy of PBT dropped faster, so we chose a heating rate of 30k/min for better thermal effect and more complete separation.

2.3 Sample volume selection

Since PBT has a significantly better thermal effect under elevated temperature conditions, as long as the sample volume is within the linear range, it can meet the test requirements, generally 10-15 mg.

Conclusion

The thermal properties of PBT were studied and tested using differential scanning calorimetry, which enabled us to determine a quick, simple and convenient quantitative test method for PBT. The test results met the requirements of the standard FZ/T 01053-2007 “Identification of Fiber Content in Textiles” and can be used for quantitative testing of PBT textile products.