High Throughput Tissue Grinder

TBM SERIES

- Remove this product from my favorite's list.

- Add this product to my list of favorites.

Product info

Overview

High Throughput Tissue Grinder is a fast, efficient and safe grinding system. Supports the extraction and purification of raw DNA, RNA and proteins including soil, plant and animal tissues, organs, bacteria, yeast, fungi, spores, and archaeal specimens. Support dry grinding, wet grinding and mixed grinding and homogenization. It can effectively improve grinding efficiency and quality, reduce labor costs, and reduce manual operation errors. It is a better choice for laboratories to replace manual grinding.

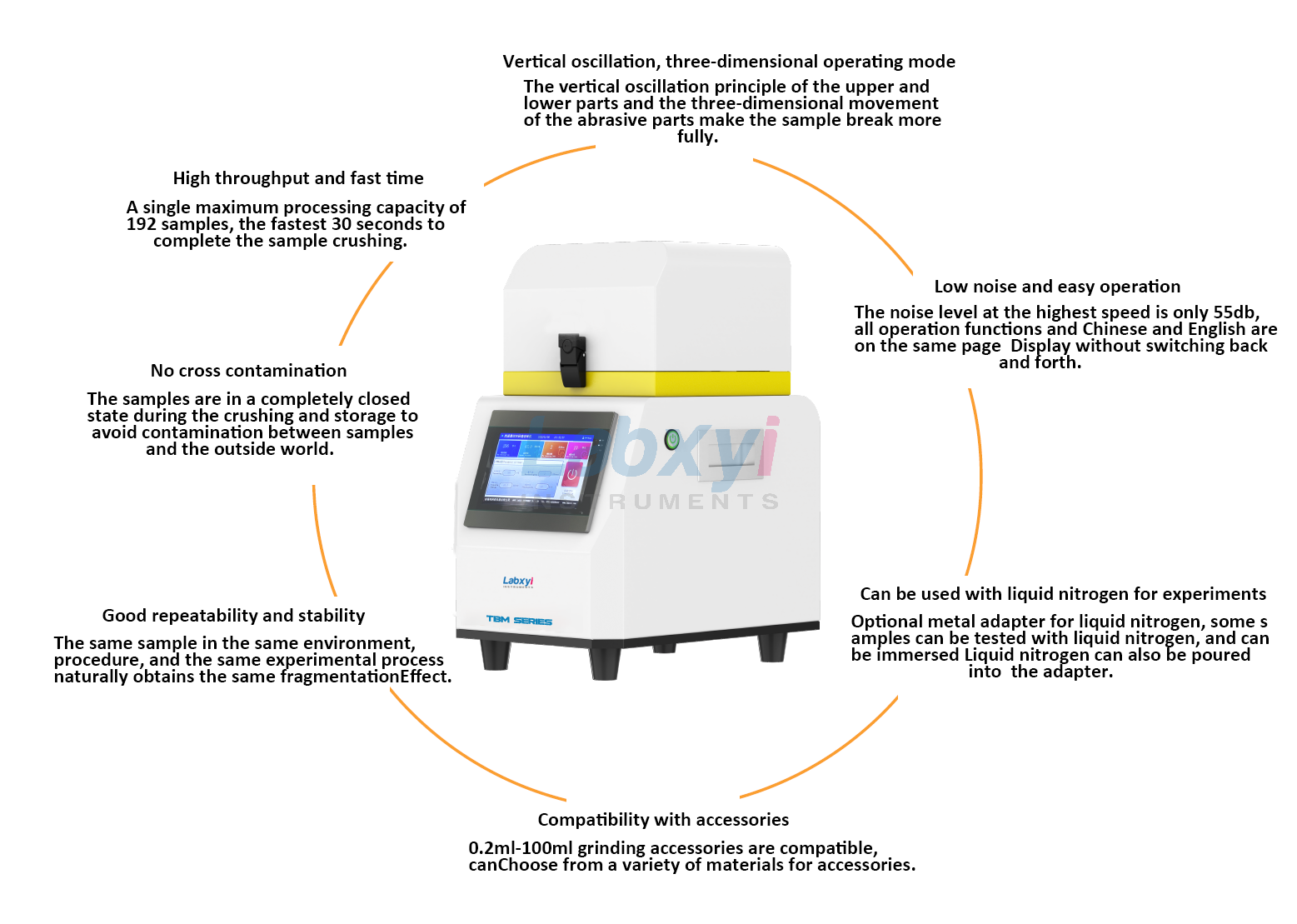

Performance introduction

- Adopt three-dimensional oscillating motion to crush samples at high speed, saving operation time;

- 7-inch LED high-resolution touch screen, beautiful interface, multiple sets of data displayed on one screen, easy to operate, Chinese and English bilingual interface;

- Multi-segment cycle control programming can be set (such as: grinding time, cycle times, gap time, etc.);

- Using high-end imported linear bearings, it runs smoothly at high speed and has a longer service life;

- Built-in LabGeni-v3.0 quality traceability system to standardize market promotion and speed up after-sales progress;

- The high hardness bearing movement rod is used with special process treatment to increase the stability and life of the product by more than 5 times.

- Equipped with exclusive cleaning and disinfectant for grinding machine accessories, no corrosion, no peculiar smell, and has the national disinfection product platform filing qualification, accessories and consumables can be reused after cleaning and disinfection, which greatly reduces the procurement cost of consumables.

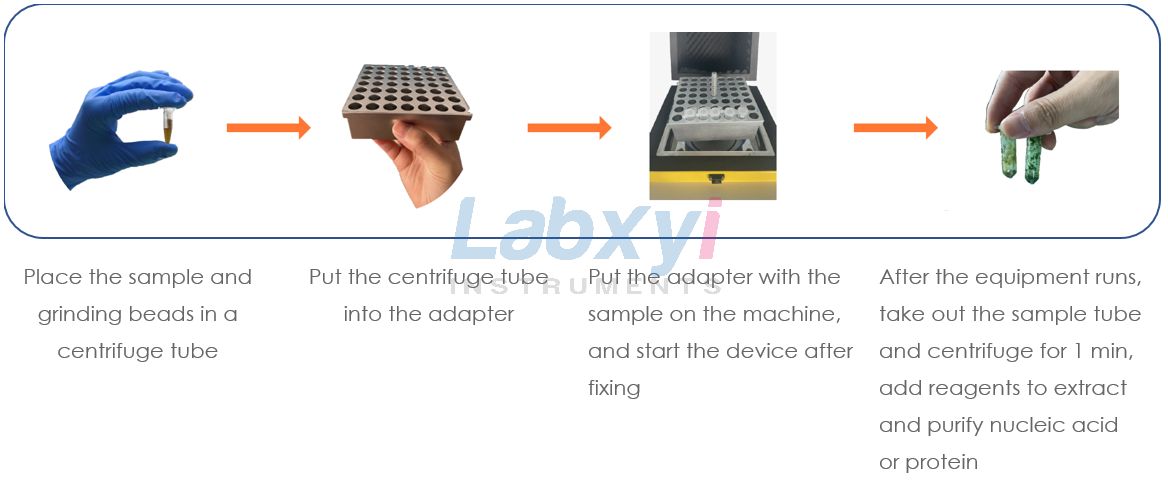

OPERATION STEPS

Working principle

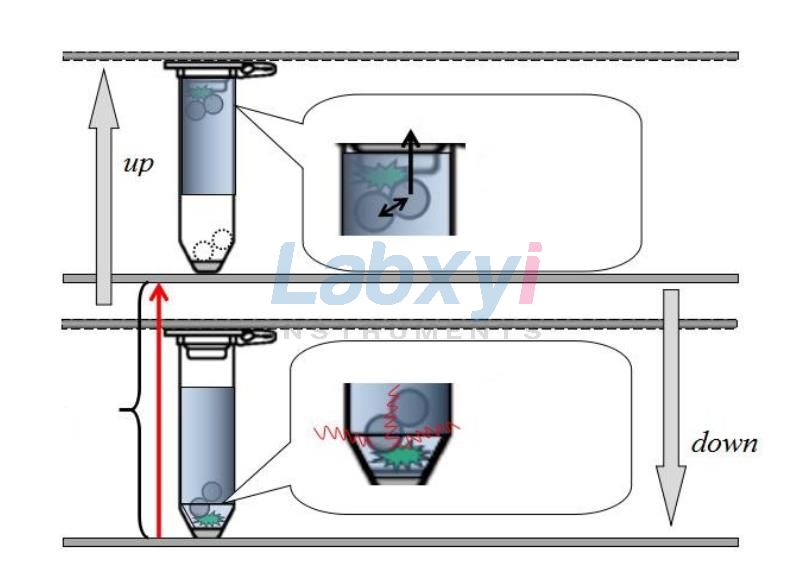

The high-throughput tissue grinder is mainly used for grinding, crushing, homogenizing, mixing, homogenizing, material dispersing, preparing, shaking, etc. of sample tissues and cells. The equipment adopts the high-frequency vertical oscillation method, selects different grinding beads to grind the samples of different shapes directly in the centrifuge tube, and the samples in the grinding tube collide with the grinding balls, and the grinding shear force and impact force generated by the grinding tube make the tissue completely Broken, so as to effectively separate and extract the original DNA and RNA.

sage

Suitable for grinding and crushing of various plant tissues including roots, stems, leaves, flowers, fruits, seeds and other samples;

Applicable to the grinding and crushing of samples of various animal tissues including brain, heart, lung, stomach, liver, thymus, kidney, intestine, lymph nodes, muscles and bones;

Suitable for the grinding and breaking of fungi, bacteria and other samples;

Applicable to the grinding and crushing of food and drug ingredients analysis and testing;

Suitable for grinding and crushing of volatile samples including coal, oil shale, and wax products;

Applicable to the grinding and breaking of plastics, polymers including PE, PS, textiles, resins and other samples.

As a new generation of tissue grinders, multi-sample tissue grinders have their irreplaceable advantages.

Main Technical Parameters

Model | TBM-24 | TBM-48 | TBM-96 | TBM-192 |

Maximum throughput of a single sample | 0.2ml-0.5ml×24 pcs 2ml×24 pcs 5ml×12 pcs 7ml-15ml×4 pcs 25ml×2 pcs | 0.2ml-0.5ml×48 pcs 2ml×48 pcs 5ml×24 pcs 7ml-15ml×8 pcs 25ml-50ml×2 pcs | 0.2ml-0.5ml×96 pcs 2ml×96 pcs 5ml×48 pcs 7ml-15ml×12 pcs 25ml-100ml×4 pcs | 96 hole plate×2pcs 2ml×192 pcs 5ml×96 pcs 7ml-15ml×24 pcs 25ml-100ml×6 pcs |

rated power | 120W | 180W | 200W | 250W |

Speed of work | 0-70HZ free setting *(1HZ=30 revolutions/second 10HZ=1.OM/S 1HZ=10RPM) | |||

Discharge particle size | ≤5um | |||

Operating hours | 1 second - 99 minutes free setting | |||

Grinding bead material and specification | Quality: stainless steel, chrome steel, zirconium oxide, tungsten carbide, quartz sand, glass beads, etc. Specifications: 0.1mm-30mm optional | |||

Grinding tube and adapter material | PE, PTFE, stainless steel, PEEK, zirconium oxide, aluminum alloy, etc. * (metal fittings can be tested with liquid nitrogen) | |||

Acceleration and deceleration time | maximum speed within 2 seconds, minimum speed within 2 seconds | |||

Noise level | ≤55db | |||

Power supply | AC220V/50HZ | |||

Dimensions (L×W×H)mm | 350×275×485 | 350×275×485 | 350×275×505 | 350×275×525 |

Weight | 30KG | 30KG | 32KG | 35KG |