Dry Wind Spray Dryer, Low temperature spray drying machine

SD-DW Series

SD-DW Series Dry Wind Spray Dryer is suitable for processing preparation of bacteriophage microcapsules, Protein feed, Creatinase, Yeast, Drosophila pupae, Lactitol, Mannitol, Graphene modified solution, Various traditional Chinese medicines, microcapsules, ACD, PF, TQB3720, collagen powder, etc.

- Remove this product from my favorite's list.

- Add this product to my list of favorites.

Product info

SD-DW Series Dry Wind Spray Dryer is suitable for processing preparation of bacteriophage microcapsules, Protein feed, Creatinase, Yeast, Drosophila pupae, Lactitol, Mannitol, Graphene modified solution, Various traditional Chinese medicines, microcapsules, ACD, PF, TQB3720, collagen powder, etc.

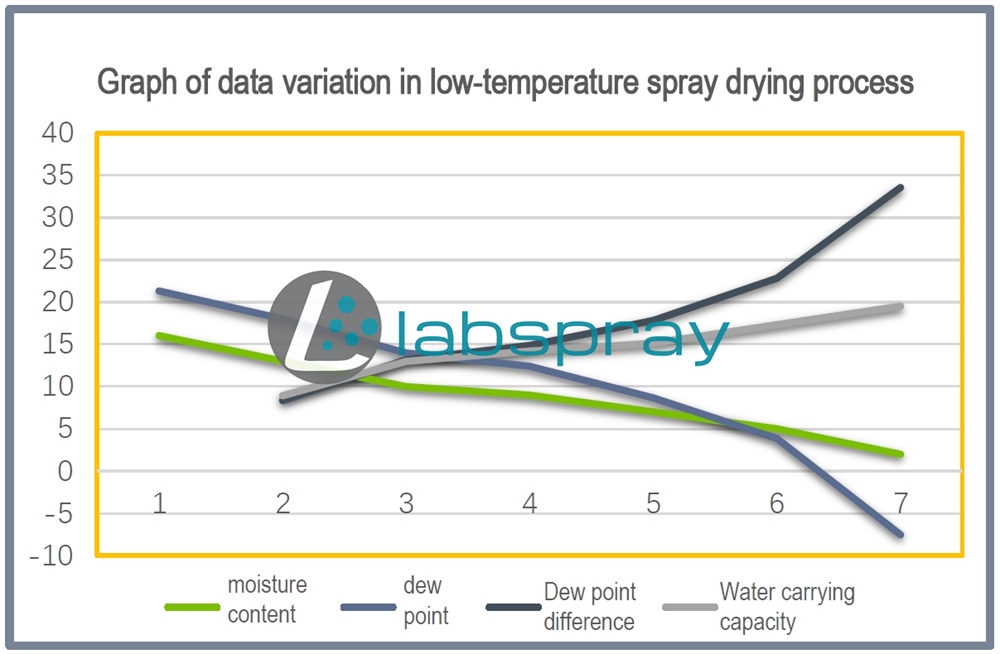

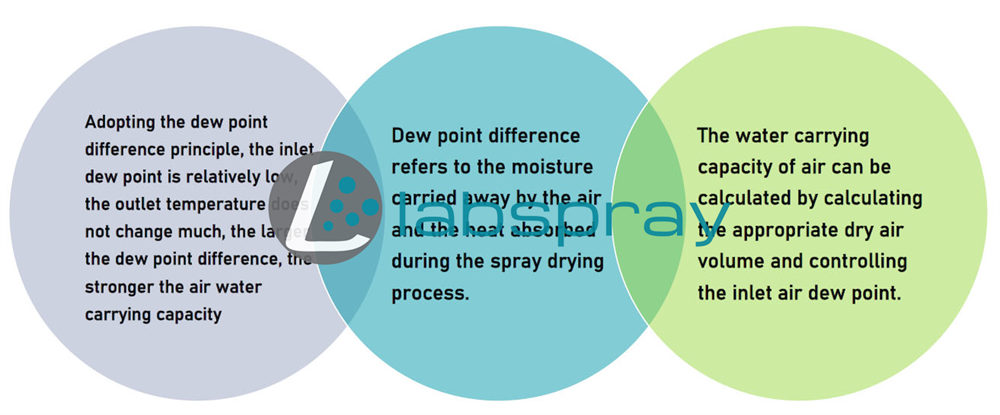

Working Principle

COMPARATION

Safety parameters

- When the equipment is running, the noise level at the distance from the equipment operator (less than 1 meter) is below 75dB

- There are obvious warning signs at dangerous parts

- Comply with the requirements of equipment safety design specifications

Dried sample

Basic parameters

- Feed rate: 50~2000ml/h

- Metal parts in direct contact with drugs must be made of 316L stainless steel, and other parts that do not contact materials, such as brackets, can be made of 304 stainless steel.

- The outside of the equipment can withstand 75% ethanol, 0.2% chlorhexidine and other disinfectants for wiping and disinfection, and can also withstand air disinfectants including 84, formaldehyde, ozone, hydrogen peroxide and acetic acid.

- The outside of the equipment can withstand 75% ethanol, 0.2% chlorhexidine and other disinfectants for wiping and disinfection, and can also withstand air disinfectants including 84, formaldehyde, ozone, hydrogen peroxide and acetic acid.

- Relevant data or operation records that need to be monitored and displayed online during the process, such as time, pressure (mechanical display), temperature, flow, alarm information, operation and program running process, can be printed out.

- The monitoring interface should include the equipment operation status (such as: preparation, operation, shutdown, etc.), the system program operation process, the data during the equipment operation (such as: temperature, pressure, air volume, etc.), the connection of the corresponding pipelines and valves, the feed pump, and the status of the atomizer opening and closing (which can be displayed on the dashboard).

- It is necessary to equip the feeding system, including Lange peristaltic pump and Lange feed pipe.

- It is necessary to equip the atomization drying system, including atomizer, air compressor, pressure regulating valve, drying tower, perspective mirror, etc.

- It is equipped with an inlet temperature sensor with a detection range of 0-250ºC

- It is equipped with an exhaust temperature sensor with a detection range of 0-150ºC

- It is necessary to equip the product recovery system, including cyclone separation, collection barrel or cup (316 stainless steel or glass), collection valve, etc.

- The electric control system is of Xinjie brand, and the electric control auxiliary system is of Schneider brand

- With cyclone collector

- Exhaust dust collector: high temperature resistant bag filter or other suitable dust collector.

- Supporting equipment (if any): dew point meter (Michel brand)

- The equipment needs to adopt appropriate design to prevent static electricity and prevent product dust from escaping from the equipment system to the operating space and surrounding environment.

- Discharge collection valve: The interface is a clamp-type quick connection

- Auxiliary equipment should be brought by itself, such as air compressor, dew point meter, cold water circulation unit, etc. The installation site only provides civil water and electricity public engineering facilities, and the system should be guaranteed to operate normally after installation.

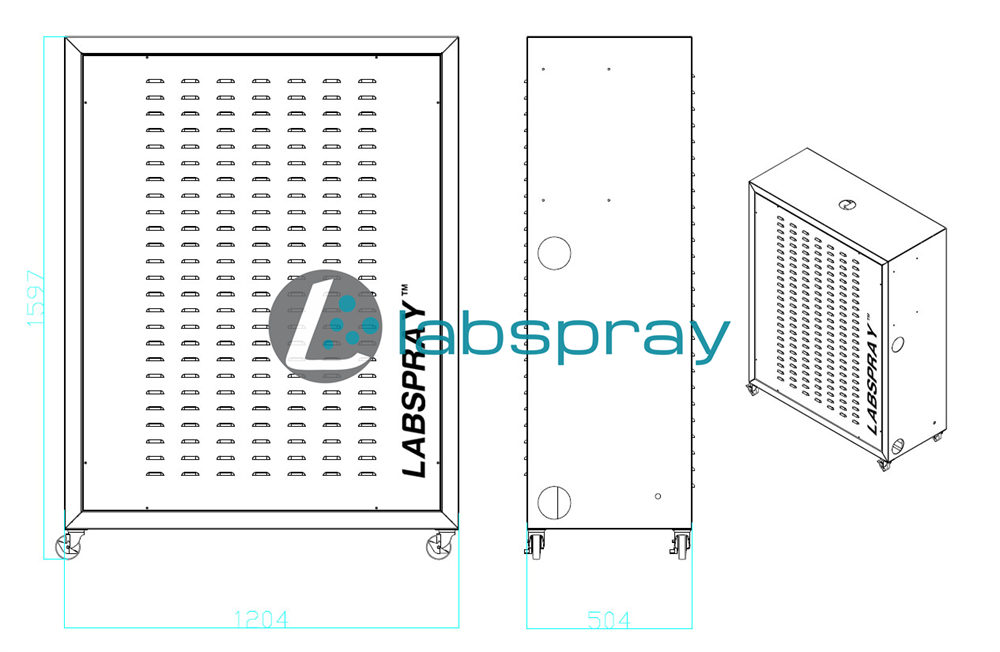

CONFIGURATION