3 square meter air cooled vacuum Freeze Dryer, 30kg~45kg per batch

FD-300F-R

- Remove this product from my favorite's list.

- Add this product to my list of favorites.

Product info

.jpg)

.jpg)

FD-300F Series

FD-300F Series | Model | FD-300F-R |

Heating type2 | Silicone oil circulation | |

Picture | | |

Drying chamber | Freeze-drying area | 3.16 m2 |

Shelves quantity | 7+1 pcs | |

Shelf Temperature | -50°C ~70°C | |

Shelf Temp. Accuracy | ± 1°C (when stable) | |

Shelf spacing | 80mm | |

Size of shelves | 500*900*20 mm | |

Roughness of inner wall & shelves | Ra ≤ 0.6μm | |

Shelf Flatness | ≤ ±0.5mm / m | |

Temperature decreasing rate | +20°C down to -40°C/ within 60 min, (no-load, entrance of silicon oil ) | |

Temperature elevating rate | -40°C up to +20°C/ within 60 min, (no-load, entrance of silicon oil ) | |

Raw material load capacity (be better) | 31 L (when thickness 10mm) | |

Material of chamber | Polish SS304 | |

Material of Shelves | Polish SS304 | |

Material of trays | SS304 | |

Tray quantity | 14 pcs bulk trays | |

Material of door | ACRYLIC | |

Stoppering device | - | |

Thermal insulation material | Polyurethane foam | |

Condenser | Shape | Vertical type, cylindrical Compact structure, better water capture ,easy to clean and defrosting |

Max temperature | ≤-85°C (Empty load) | |

Water-capture capability | > 60 Kg/24h | |

Defrost | Water soaking | |

Material | SS304 or SS316 (Optional) | |

Condenser temp. Decreasing | +20°C~ 40°C, within 30 minutes | |

thermal insulation material | Polyurethane foam | |

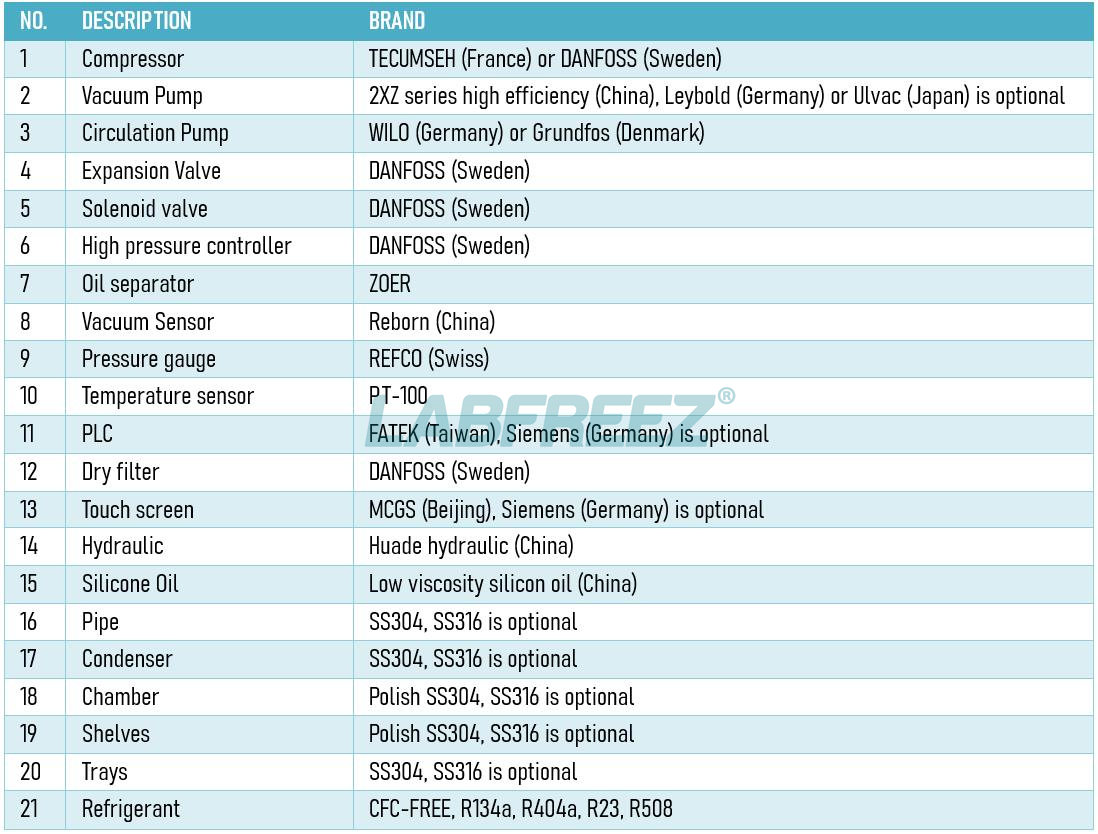

Refrigeration unit | Compressor | France original imported TECUMSEH full closure compressor * 2 sets |

Refrigerant | CFC-FREE R507 & R23 | |

Cooling type | Air cooled | |

Pressure controller | DANFOSS | |

Expansion valve | DANFOSS | |

Vacuum System | Double stage rotary vane pump | Standard vacuum pump (Ulvac, Leybold and etc is optional) |

Quantity | 1 set | |

Vacuum gauge | Reborn | |

Chamber pumping rate | Atmosphere to 10 Pa less than 30 minutes(in dry condition) | |

System Maximum vacuum | ≤ 5Pa | |

System leaking rate | ≤ 10 Pa.l / sec | |

Liquid circulation system | Liquid | low viscosity silicon oil( 25°C, 5cst ) |

Liquid tubing material | AISI 304, welding, heat keeping | |

Circulation pump | GRUNDFOS, original imports, web rotor canned pump, From Denmark brand, world famous brand | |

Circulation pump quantity | 1 set | |

Heating rate | 3 kW | |

Heating control style | Solid-state relay | |

Stainless steel plate heat exchanger | Well-known brands | |

Temperature sensor | PT-100 platinum resistance | |

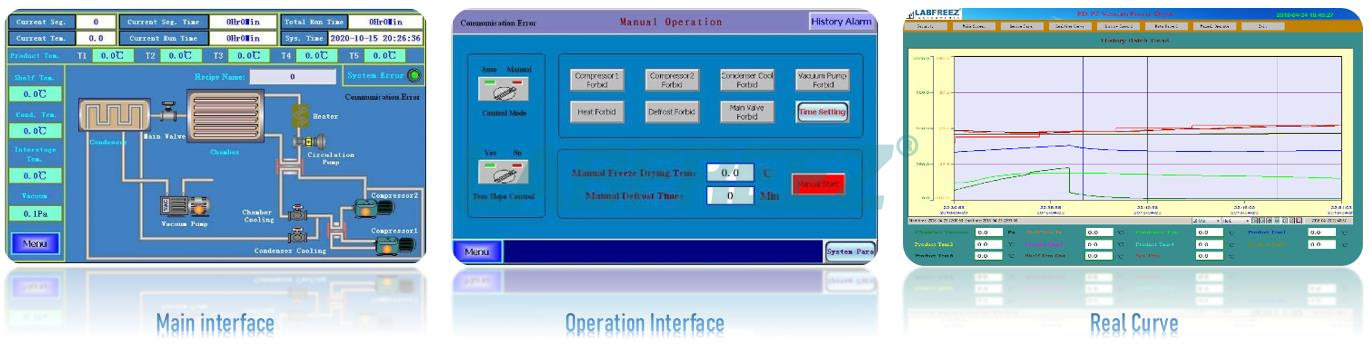

Control system | Control style | Automatic and manual control |

PLC | FATEK | |

Touch screen | MCGS | |

Intermediate relay | CHINT | |

AC contactor | CHINT | |

Air circuit-breaker | CHINT | |

Wiring terminals | Well-known brands | |

Safety protection | Whole machine protection | All safety conditions are ready for whole machine, machine can start running. |

Operation protection | Electrical system have logic interlock, control and protection function | |

Vacuum pressure | Available | |

Heating system | Available | |

Power cut and supply | With safety protection measure | |

Products protection during sublimation process | Heat cutting if vacuum lack | |

Condenser protection when vacuum pump start | Interlock | |

Basic parameters | Vacuum degree | ≤5 Pa |

Dimension | 1200x2300x1700 (mm) | |

Max Power | MAX 15KW (working power is far less) | |

Weight | 1500 kg | |

Data Process | RS232 Interface or USB | |

Control method | PLC auto + manual | |

Design, production, installation standards | As GMP | |

Other main spare parts brand | High pressure protection device | When system’s air discharge pressure exceeds allowed pressure, machine automatically stops working, to avoid an accident. |

expansion valve | DANFOSS (Denmark) | |

Top cover valve | Castel (Italy) | |

solenoid valve | DANFOSS (Denmark) | |

Oil separator | ZOER | |

High pressure controller | DANFOSS (Denmark) | |

Disacidify filter | DANFOSS (Denmark) | |

Pressure meter | LR/REFCO(Germany/Swiss) oil submerge pressure meter | |

Water cooling condenser | Well-known brand |

.jpg)