AUTOMATIC INTELLIGENT MICROWAVE DIGESTION SYSTEM

MW-DE-2040

MW-DE-2040 fully automatic intelligent microwave digestion instrument, its diamond body adopts a thickened and enhanced 316L stainless steel microwave resonant cavity, which can It accommodates digestion tanks of various specifications and processes 1-40 samples.

- Remove this product from my favorite's list.

- Add this product to my list of favorites.

Product info

MW-DE-2040 fully automatic intelligent microwave digestion instrument, its diamond body adopts a thickened and enhanced 316L stainless steel microwave resonant cavity, which can It accommodates digestion tanks of various specifications and processes 1-40 samples. It has an audit trail function, allowing real-time viewing of instrument operation records to ensure data integrity, operator hierarchical management, and multiple password protection.

.jpg)

.jpg)

Innovation

- Full tank temperature monitoring and control technology, scanning, detecting and controlling the temperature of each digestion tank from the bottom and displaying it in real time

- full tank pressure monitoring and control technology, which can detect and control the pressure of each digestion tank to ensure the safe operation of the equipment

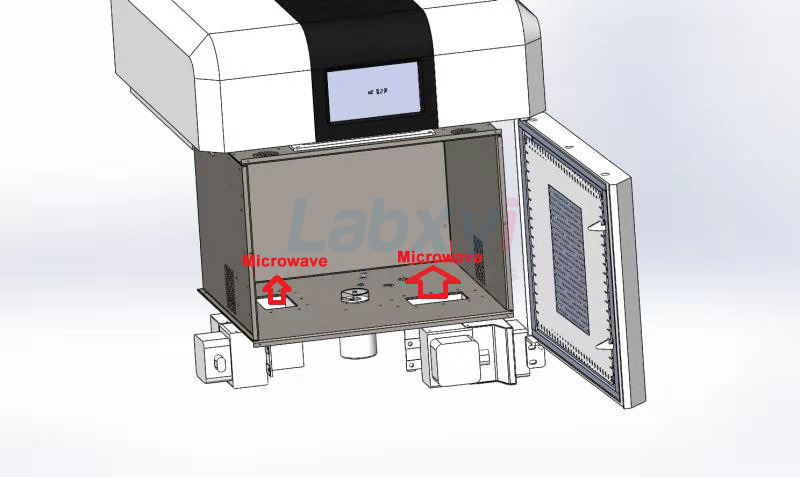

- Bottom microwave emission ensures consistent temperature of the 40-position inner and outer ring digestion tanks

- Non-pulse continuous microwave emission technology ensures continuous microwave emission

- New sealed vertical explosion-proof safety pressure relief technology for digestion tanks

- Rotor identification system automatically identifies the number of rotors

- Three-dimensional resonance arrangement design of double magnetrons ensures uniform microwaves in the furnace cavity

- Special stainless steel microwave resonant cavity has the body of a diamond and is thickened and reinforced with an original design, with a volume of 66L. Inner cavity is sprayed with multiple layers of PFA (modified polytetrafluoroethylene) to prevent long-term corrosion from strong acids.

- LCD screen controls and displays temperature, heating time, constant temperature time, power and temperature and time curves in real time at a glance; built-in application methods. The user can call

- It can be used in microwave experiments with high- precision control of the reaction process such as ultra-high pressure sealed microwave digestion, high-throughput sealed microwave digestion, sealed organic solvent extraction, sealed organic synthesis, etc.

- Can be connected to an external PC to achieve more functions (optional)

- Can connect to IPAD or mobile phone through wireless WIFI to observe the operation of the digestion tank in the furnace cavity (optional)

Reaction tank components (various options)

- High-throughput reaction tank

- Inner tank material: PFA, TFM, quartz, etc. optional

- Outer tank material: aerospace composite material or aerospace PEEK optional

- Maximum temperature:330℃ (TFM inner tank);600℃ (aerospace composite outer tank)

- Maximum pressure: 22000psi

- Volume: 60ml, 100ml, 110ml optional

- Batch processing capacity:Standard: 1-40 position (60/30ml)/1-34 position (110/55ml) Mini: 1-18 position (60/30ml)/1-16 position (110/55ml)

- Application scope: food, soil, sediment, metal, alloy, geology, Chinese medicinal materials, capsules, chemicals, agricultural samples, plant materials, biological materials, etc.

.jpg)

various microwave digestion tanks provide by LABXYI

- Can be LABXYI , CEM (Pearl), Milestone, etc.

- Well-known brand manufacturers of microwave digestion instruments provide alternative microwave digestion tanks

- Inner tank material: TFMPFA and other polytetrafluoroethylene materials

- Outer tank material: PEEK and other aerospace composite materials