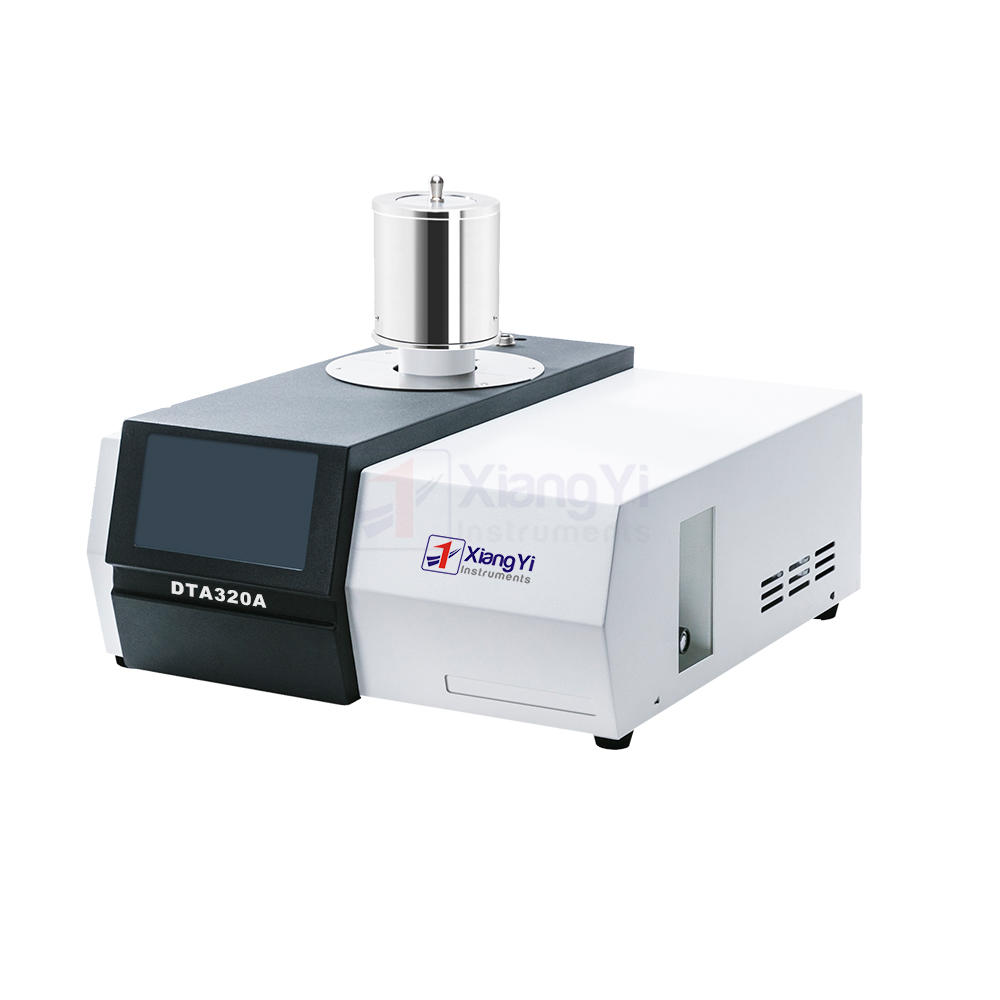

High temperature differential thermal analyzer

DTA320A

DTA3320A Differential thermal analyzer has been granted the National Patent. The Patent Number is 201120337217.3

- Remove this product from my favorite's list.

- Add this product to my list of favorites.

Product info

Product introduction

Our company self-developed thermal analyzer series products are mainly oriented to industrial users, scientific research and teaching,widely used in all kinds of materials and product research and development in chemical field,process optimization and new quality inspection, etc, mainly measuring heat-related physical and chemical changes, such as physical melting point, crystallization melting hot phase crystallization heat, heat, heat stability (oxidation induced phase), glass transition temperature, etc.

How the instrument works

In DTA experiments, changes in sample temperature are caused by phase transitions or endothermic or exothermic effects of reactions. Such as: phase transition, melting, transformation of crystal structure, boiling, sublimation, evaporation, dehydrogenation reaction, fragmentation or decomposition reaction, oxidation or reduction reaction, destruction of lattice structure and other chemical reactions.

Instrument features

The main control chip of the instrument adopts the Cortex-M3 core ARM controller, which has faster calculation processing speed and more precise temperature control.

Using USB two-way communication, the operation is more convenient.

Adopt 7-inch 24bit color full-color LCD touch screen, the interface is more friendly.

The platinum rhodium alloy sensor is used, which is more resistant to high temperature, corrosion and oxidation.

Technical parameters

MODEL | DTA320A | DTA332 | DTA320C |

Picture | | | |

temperature range | RT~1150°C | RT~1350°C | RT~1500°C |

Measuring range | 0~±2000μV | 0~±2000μV | 0~±2000μV |

DTA sensitivity | 0.01μV | 0.01μV | 0.01μV |

DTA accuracy | 0.1μV | 0.1μV | 0.1μV |

Heating rate | 1~80°C/min | 1~100°C/min | 1~100°C/min |

Temperature resolution | 0.1°C | 0.1°C | 0.01°C |

Temperature accuracy | ±0.1°C | ±0.1°C | ±0.1°C |

Temperature repeatability | ±0.1°C | ±0.1°C | ±0.1°C |

temperature control | Heating: program control, parameter adjustment can be made according to needs, constant temperature: program control, constant temperature time arbitrarily set | ||

Furnace structure | The furnace body adopts an open-top structure, which replaces the traditional lifting furnace body, with high precision and easy operation | ||

Atmosphere control | Automatic switching of internal programs | ||

Data interface | Standard USB interface, supporting data cable and operating software | ||

Display method | 24bit color, 7-inch LCD touch screen display | ||

Parameter standard | Equipped with standards, with one-key calibration function, users can calibrate the temperature by themselves | ||

Baseline adjustment | Users can adjust the baseline through the slope and intercept of the baseline | ||

Power supply | AC 220V 50Hz (110V 60Hz is optional) | ||

Main packing list

Item No | Item Name | Qty |

1 | Power cord 3*1.5 | 1 |

2 | USB cable | 2 |

3 | Tin grains | 1 |

4 | 10A fuse | 5 |

5 | 160mm camera | 1 |

6 | Ear wash ball | 1 |

7 | ceramic crucible | 100 |

8 | Aluminum crucible | 100 |

9 | ceramic cover | 4 |

10 | sample rod | 1 |

11 | sample spoon | 2 |

12 | 8*5 PE plastic pipe | 6 |

13 | copper joint | 2 |

14 | raw tape | 1 |