Fully automatic spiral inoculator

MEDIASINOC-9

- Remove this product from my favorite's list.

- Add this product to my list of favorites.

Product info

Introduction

Principle: Place the plate on the turntable of the spiral inoculator. After the sampler absorbs the bacterial suspension to be tested, it contacts the agar surface in the center of the petri dish. While the plate rotates, the sample needle moves from the center of the plate to one side, and bacterial suspension is inoculated onto the agar surface. After inoculation, the cultured colonies were distributed according to Archimedean spiral, and became more and more dispersed as the radius increased.

Spiral plate method: Use a spiral inoculator to inoculate the sample on a plate. After the sample is inoculated, the colonies are distributed on the spiral trajectory, and the distribution becomes more and more sparse as the radius increases. Using a special counting grid to count the colonies on the plate from the periphery to the center, the number of microorganisms in the sample can be obtained.

The spiral inoculation method is included in the

- FDA

- AOAC (American Association of Analytical Chemists)

- APHA (American Public Health Association)

- AFNOR (French Association for Standardization)

- IS07218

- Food Microbiology Testing-Culture Quality requirements for bases and reagents

- Colony counting detection method in food and cosmetics-Spiral plate method.

Application areas

It is suitable for testing the total number of bacterial colonies on samples with a large number of bacteria, such as government testing agencies, food, pharmaceuticals, and cosmetics industries.

Microbiology research units, users who need to pour a large number of gradient dilution plates every day.

Culture medium quality control, such as culture medium production companies, large food, pharmaceutical, and cosmetics companies.

Technical Parameters

1. Environmental requirements: temperature: 5-40℃, humidity: 20%-90%; power requirements: 110-240V, 50Hz. |

2. Only one plate can be used to quantitatively detect microorganisms in samples with bacterial content ranging from 30 to 4 × 10⁵cfu/ml (9cm plate). The colony dispersion on the plate is good, there is no colony interference on the edge of the dish, it is easy to count, and the results are accurate; |

3. The core of MEDIASINOC-9 is an inoculation device controlled by a microprocessor. Pressing a button will automatically complete the process of sample absorption, spiral inoculation, disinfectant and water washing; |

4. Using Teflon inoculation needle, no sample remains, and the unique inoculation needle balancing device automatically handles plates with different agar thicknesses; the agar plate will not be scratched; |

5. Logarithmic mode and linear mode are optional. Depending on the number of bacteria in the sample, multiple inoculum amounts can be selected in different modes; |

| vaccination mode | Inoculation volume (μl) |

9cm | Logarithmic mode | 50, 100, 200, 400, 1000 |

linear mode | 50, 100, 200, 400, 1000 |

Related indicators corresponding to commonly used inoculation amounts | ||

9 cm plate inoculation volume | Counting range | The number of plates that can be aspirated at one time |

50μl (logarithmic mode) | 400~4×10 ⁵ cfu/ml | 20 |

100μl (logarithmic mode) | 200~2×10°cfu/ml | 10 |

200μl (logarithmic mode) | 30~1×10 ⁵ cfu/ml | 5 |

400μl (logarithmic mode) | 10~750cfu/ml | 2 |

6. The precision syringe has a capacity of 1000 μL; when the inoculation volume is 50 μl, the typical inoculation time is 8 seconds. |

7. The theoretical minimum detection limit is 2.5cfu/ml (400μL linear mode); the maximum error is <5cfu/ml when the number of colonies is 400cfu/ml. Powerful microprocessing The inoculator is automatically controlled by software, and the entire process from sample processing to inoculation is completed automatically. The inoculator algorithm can automatically process plates with different agar thicknesses. |

8. The sample inoculation trajectory is an Archimedean spiral, with two inoculation modes available: uniform or logarithmic. It will produce a 1000-fold dilution effect after inoculation on a 9cm plate. |

9. Loading samples, inoculating plates and cleaning the inoculating head can be completed with one button press. There are no consumables required, especially vaccinations, and no subsequent costs. |

10. There is a cleaning fluid storage system that can complete the automatic cleaning cycle to facilitate the preparation of the next sample, ensure the continuity of operations, and improve efficiency. |

11. The microprocessor detects the movement and relative position of the inoculation head, inoculation rack and turntable , and compares the data obtained with the factory settings to generate accurate correction data. |

12. The host shell is made of corrosion-resistant polyurethane, the control keys use a color touch screen, and the parameters can be set to selectable and locked modes; |

13. Automatic cleaning system, One-click cleaning, use disinfectant twice and rinse twice with sterile water. When the inoculation needle is clogged, it can be rinsed in reverse; the disinfectant uses hypochlorine Sodium acid or alcohol will do; |

14. Spiral inoculation has two modes: manual and automatic. Samples can be drawn directly from non-standard containers; several plates can be continuously inoculated by drawing one sample. |

15. An optional inoculation table with adjustable size can be used for various sizes of plates; |

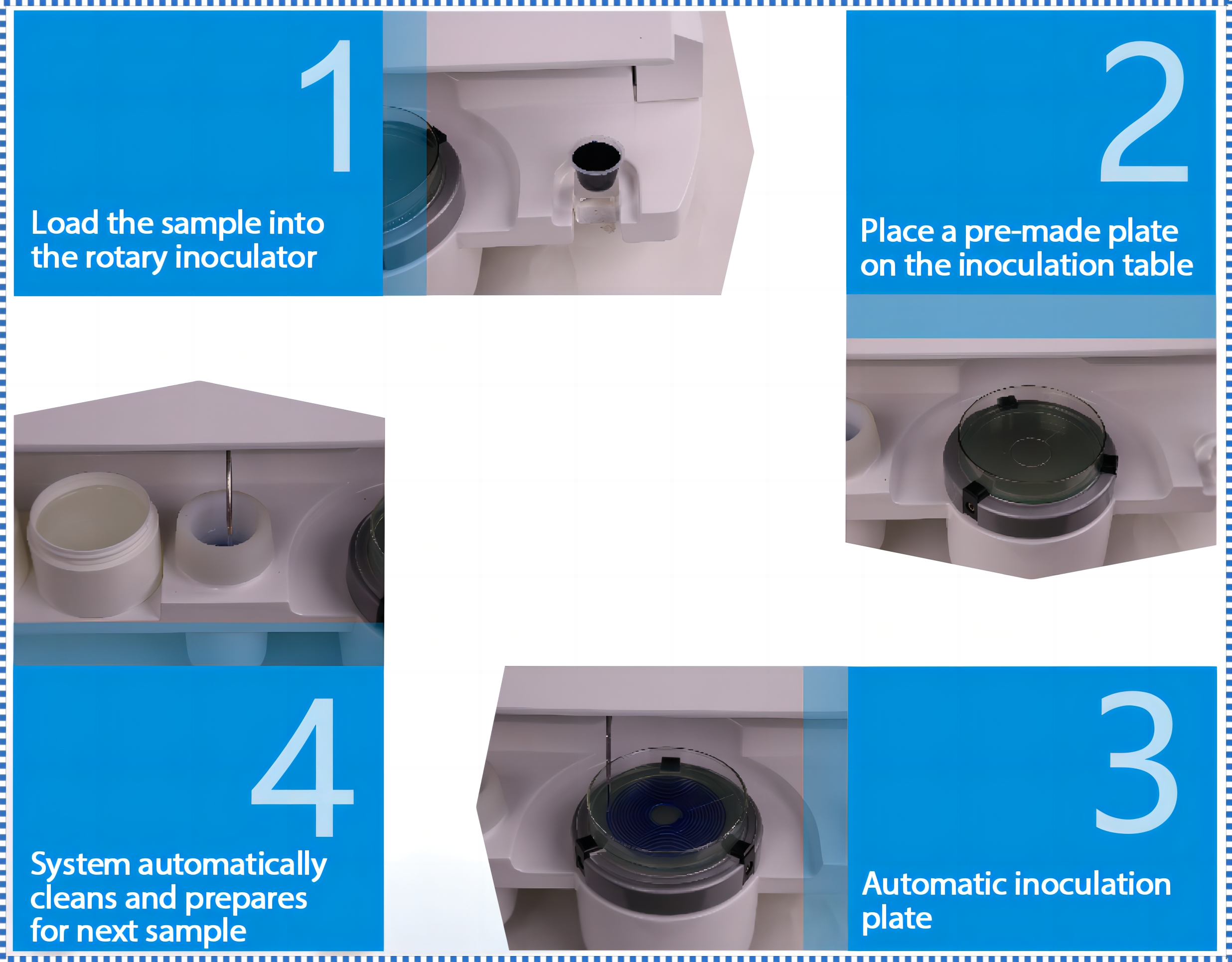

Operation Steps

Project | Describe |

Flat | 9cm |

Inoculum volume | 50~1000μL |

vaccination mode | Optional logarithmic or linear mode |

Counting range(9 cm dish) | 30~4×10⁵ cfu/ml |

Dimensions (w×d×h) | 535×410×365mm |

power supply | 100~240V/50-60Hz |