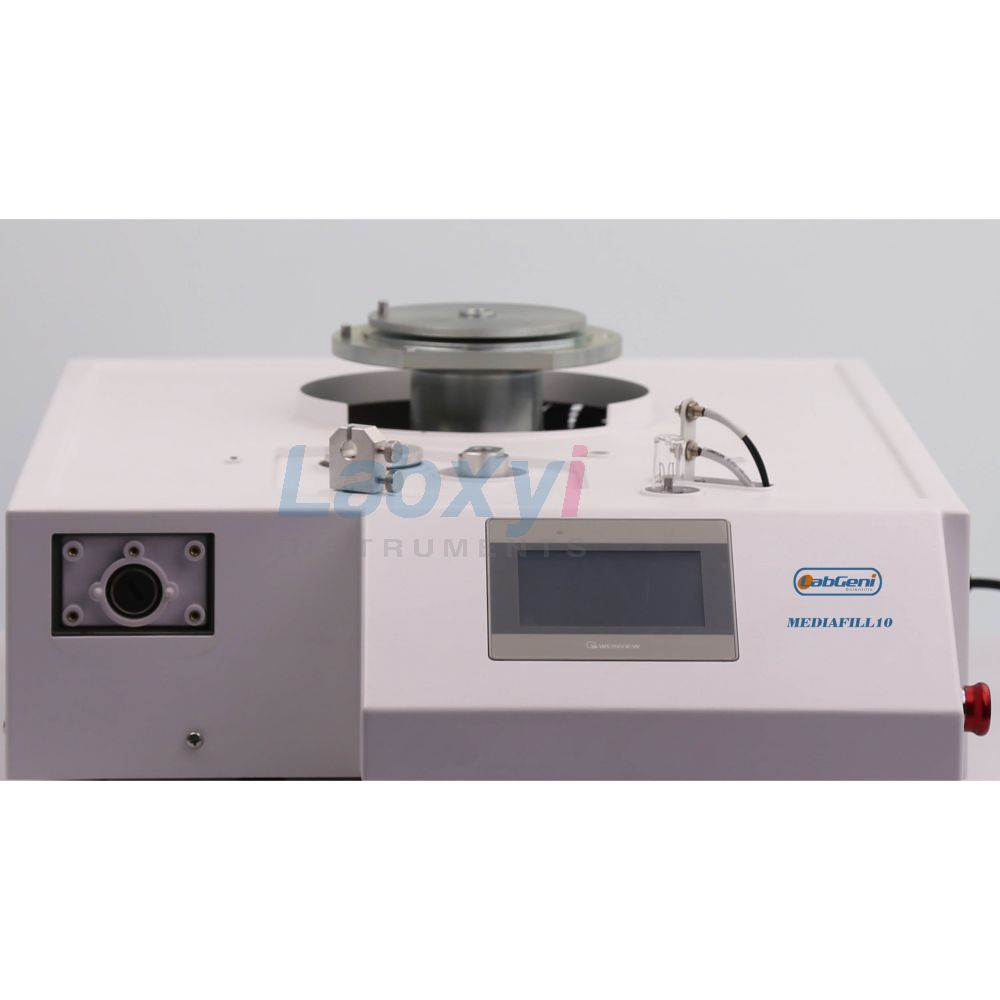

Automatic media Dispenser, culture petri dish dispenser

MEDIAFILL10 400

In modern laboratories, it is essential to dispense aseptic media, and there is an increasing demand for media quality. The MEDIAFILL dispenser dispensing system offers a unique and flexible dispensing mode that dispenses multiple plates and occupies a small laboratory bench space to complete the dispensing process.

- Remove this product from my favorite's list.

- Add this product to my list of favorites.

Product info

https://youtu.be/3W2xsKx6i34

In modern laboratories, it is essential to dispense aseptic media, and there is an increasing demand for media quality. The MEDIAFILL dispenser dispensing system offers a unique and flexible dispensing mode that dispenses multiple plates and occupies a small laboratory bench space to complete the dispensing process.

A perfect fit with the media preparer allows you to dispense 1-10 liters of sterile media at once to meet the needs of small laboratories.

MEDIAFILL dispenser is a compact, highly automated plate dispenser that requires only a small amount of laboratory bench space. Its feature is to explain the operation through its own explanation, just as all functions can be easily controlled through the graphical user interface. Once the plate dispensing process is initiated, the entire system can be operated stably without the operator. The filling area of the filling machine must be equipped with an ultraviolet sterilization lamp to ensure that the filling area is clean.

Easy to operate

All of the MEDIAFILL dispenser's features are easily controlled through a graphical user interface that is displayed full screen. The operation of the system is completely explained by itself, just as all functions are explained in plain text, so that in fact, the operation of the machine does not require an operation manual..png)

.png)

.png)

.png)

Reliable automation

The MEDIAFILL dispenser guarantees reliable and independent operation. The plates are mechanically transmitted in the system during the dispensing process and monitored by a set of sensors. Typical disposable plastic plates vary in diameter and shape, but the machine can be adjusted automatically without problems, so that there is no trouble during the entire operation. After preparing 9 liters of medium, it can be dispensed into 540 plates by pressing a single button.

Technical Parameters

MODEL | MEDIAFILL-10 200 | MEDIAFILL-10 400 |

Dispensing hose | 25# (0.2~1120ml/min) or 17# (0.3~1780ml/min) | |

Dispensing accuracy | 1% (20ml) with a system calibration program, to ensure easy and accurate dispensing. | |

Dispensing speed | 400pcs/h (Dual pump head, 20ml, φ90mm) | 800pcs/h (Dual pump head, 20ml, φ 90mm) |

Petri dish holder | 25pcs/grid, 9 grid, can be placed up to 175 petri dishes (φ 90mm), φ 60mm dish holder is optional | 40pcs/grid, 9 Grid, can hold up to 280 culture dishes (φ 90mm) at a time, φ 60mm dish holder is optional |

Dispensing place | 3 holes in φ 90mm (φ 60mm optional) | 6 holes in φ 90mm (φ 60mm optional) |

Shaking function | N/A | Yes, Make medium distribution more even & smooth |

Semiconductor Cooling | N/A | Optional, Cooling the medium |

Print module | N/A | Optional, Print production date, expiration date, batch number, etc. on the culture dish |

UV LAMP | 11W, 254nm, Disintegration of separate areas, low risk of contamination, Automatic reminder replacement, 13000h life time | |

Control | Large touch screen, Easy to operate, simple and intuitive to set parameters | |

Cleaning & disinfection | Dish and rotary plate are removable for cleaning and disinfection | |

Alarm | Failure alarm function | |

Dimensions | 640*515*725mm | 725*635*1000mm |

Packing size | 950*730*1080mm | 925*835*1300mm |

Weight | 72kg / 92kg | 82kg / 112kg |

OPTIONAL

Item Description | |

MEDIAFILL001 | Label printing for MEDIAFILL-10 200/400 |

MEDIAFILL002 | Label printing interface for MEDIAFILL-10 200/400 |

MEDIAFILL003 | Cooling and shaking forMEDIAFILL-10 400 |

MEDIAFILL004 | 60mm diameter petri dish holder and supporting petri dish |