Oxygen, nitrogen & hydrogen analyzer

EA-ONH6K

- Remove this product from my favorite's list.

- Add this product to my list of favorites.

Product info

Introduction

EA-ONH6K series oxygen, nitrogen and hydrogen analyzer is a professional laboratory analysis instrument with high sensitivity, high precision and high stability. Due to the modular design, future hardware and software upgrades will be more convenient.

Analysis principle

Oxygen, nitrogen and hydrogen in metal and non-metal solid materials are detected by inert gas melting method. According to the different methods of hydrogen measurement, it can be divided into two types:

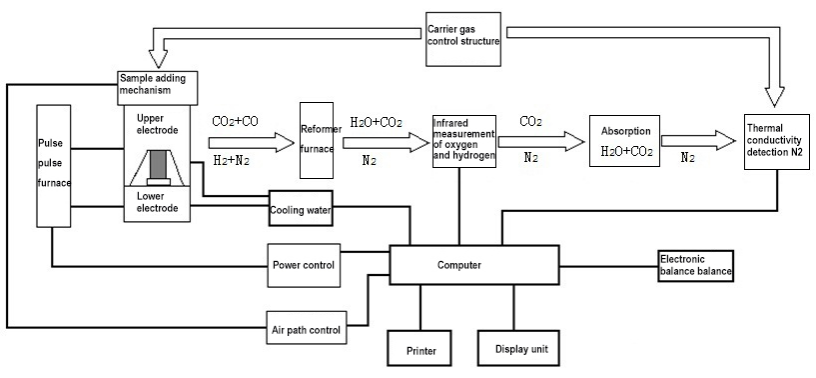

Infrared absorption method to measure hydrogen: when using infrared absorption method to measure hydrogen, an EA - ONH6 K oxygen, nitrogen and hydrogen analyzer can be used to simultaneously measure the content of the three elements of oxygen, nitrogen and hydrogen, and the weighed sample

is placed in a graphite crucible , in a helium (argon can be used to save cost when nitrogen is not measured) gas flow and melted by high temperature heating. The oxygen in the sample reacts with the carbon in the graphite crucible to form carbon monoxide (CO), and the nitrogen and hydrogen in the sample escape in the form of nitrogen and hydrogen respectively. In the furnace, carbon monoxide (CO) is converted to carbon dioxide (CO 2 ), H2 is converted to H 2 O, and nitrogen does not react. The mixed gas after passing through the reformer is sent to the CO 2 infrared detection cell and the H2O infrared detection cell. According to the detected content of carbon dioxide (CO 2 ) and H 2 O, the content of oxygen and hydrogen in the original sample can be calculated. Subsequently, after carbon dioxide (CO 2 ) and water in the mixed gas detected by infrared are absorbed, the remaining mixed gas of nitrogen and helium is detected through a thermal conductivity detection cell. After the nitrogen is separated, it enters the thermal conductivity cell to detect the nitrogen content. The test results are directly given after computer data processing. (see picture 1)

figure 1

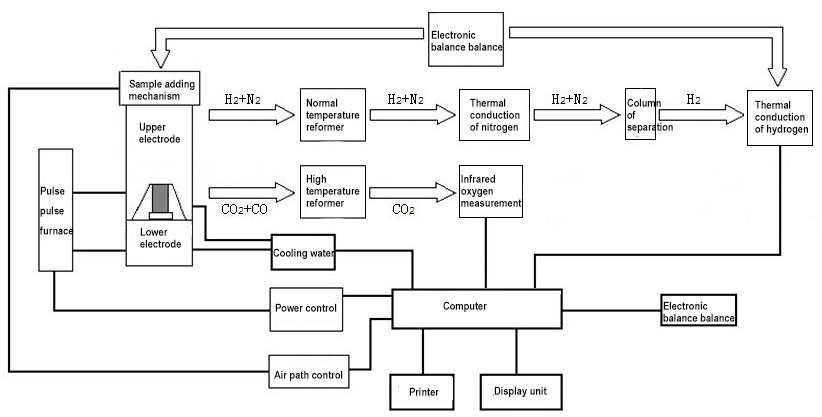

Hydrogen measurement by thermal conductivity detection method: when hydrogen is measured by thermal conductivity detection method, only oxygen and nitrogen content or oxygen and hydrogen content can be measured in one measurement. Put the weighed sample in a graphite crucible, and melt it by heating at high temperature in a flow of helium (argon can be used when nitrogen is not measured). The oxygen in the sample reacts with the carbon in the graphite crucible to generate carbon monoxide (CO), and the nitrogen in the sample escapes in the form of nitrogen gas (hydrogen in the form of hydrogen gas). These mixed gases are divided into two paths by the carrier gas: one is sent to High-temperature reformer, in which carbon monoxide (CO) is converted into carbon dioxide (CO 2 ), the mixed gas after passing through the reformer is sent to the CO2 infrared detection cell, where the content of carbon dioxide (CO 2 ) is detected, according to This calculates the oxygen content in the original sample. After the carbon dioxide (CO 2 ) and water in the mixed gas passing through the room temperature reformer in the other way are absorbed, the remaining nitrogen (or hydrogen) is detected through the thermal conductivity detection cell, and the test result is directly given after computer data processing. (See Figure 2)

figure 2

Applicable scope of the instrument

Determination of oxygen, nitrogen and hydrogen content in ferrous metals, non-ferrous metals, various alloys, zirconium, titanium, molybdenum, nickel, ceramics, rare earths, magnetic materials and other solid materials.

Technical Specifications

2.2 Analysis scope:

Hypoxia: 0.0001%~0.5% Hyperoxia: 0.5%~20%

Low nitrogen: 0.0001%~2.0% High nitrogen: 0.5%~50%

Low hydrogen: 0.0001%~0.005% High hydrogen: 0.001~0.1%

The analysis range can be extended by reducing the sample weighing.

2.3 Minimum reading: 0.000001%

2.4 Instrument accuracy

Oxygen: SD:≤0.0001% or RSD≤1.0%*

Nitrogen: SD:≤0.0001% or RSD≤1.0%*

Hydrogen: SD:≤0.2ppm or RSD≤2.0%*

Note: * Subject to not greater than the standard deviation or uncertainty of the standard.

2.5 Analysis time:

Oxygen: 120~180S

Nitrogen: 120~240S

Hydrogen: 120~180S /120~240S (infrared absorption method/thermal conductivity method)

(It can be set arbitrarily according to the analysis material).

2.6 Electronic balance weighing accuracy (one ten-thousandth): 0.0001g

2.7 Analysis method:

Oxygen: infrared absorption method

Nitrogen: Thermal Conductivity Method

Hydrogen: Infrared absorption method/thermal conductivity method.

2.8 pulse heating furnace:

Maximum current: 1500A;

Maximum power: 8KVA;

Maximum temperature: 3500°C;

2.9 Carrier gas: 99.999% high-purity argon/high-purity helium, 0.40MPa.

2.10 Power gas: ordinary nitrogen or purified compressed air (removing oil and water), 0.25MPa.

2.11 Chemical reagents: magnesium perchlorate, alkali asbestos.

Technical characteristics

3.1 Machine structure

The whole machine adopts modular integrated design, and the four independent modules of pulse electrode furnace, gas system, circuit system and detection system are integrated into one floor-standing host, with a simple and elegant appearance. With automatic zero adjustment and high and low range automatic switching function. A general-purpose 64-bit computer is used to control the whole machine. The host uses a 32-bit embedded ARM microcomputer control and a 24-bit high-precision data acquisition system to meet the requirements for high control accuracy and speed.

3.2 Electrode Furnace System

The pulse electrode furnace has a high heating temperature and adopts program control power. It can provide various programmed heating methods such as constant power heating, slope heating, and segmental heating to improve the analysis accuracy. It is suitable for low melting point materials such as aluminum alloys to high melting points such as tungsten alloys. Rapid analysis of materials. The electrode is suitable for various types of crucibles. According to the release conditions of different samples, various crucibles including sleeve crucibles and high-temperature crucibles can be selected, which can effectively reduce the user's cost of use.

The electrode cooling adopts a single-cycle independent cooling system, which can be directly connected to external circulating water or external water cooling device, and has the characteristics of good cooling effect and high reliability.

3.3 Gas system

Due to the integrated floor-standing design of the whole machine, the space is open, the connection routes of the gas system are greatly reduced, and the gas system of the whole machine is more concise and reliable.

Air circuit components include solenoid valves, cylinders, air pipes, and air circuit joints, all of which are imported components (the life of the solenoid valve can reach more than one million times). The unique three-axis guide cylinder can ensure the stable lifting of the electrode, ensure the good contact between the graphite crucible and the upper electrode, and ensure the uniform force of the graphite crucible, which is conducive to long-term high-temperature heating. The automatic blanking furnace head with air curtain protection and automatic air purging mechanism effectively guarantee the analysis accuracy of oxygen element.

The furnace head is a split structure, the upper and lower electrodes are easy to disassemble and replace, and the lower electrodes are made of high-temperature alloy materials, which have a long service life and low cost of use, avoiding the trouble of using a whole furnace head and replacing electrodes by professional technicians.

Pollutants are discharged from the top of the furnace and do not enter the system. The operation is convenient and the requirements for the sealing of the system are not high.

The sampling device is simple and can automatically inject samples, which is convenient for maintenance and cleaning when abnormal failures occur.

The electronic micro-flow sensor is used for high-precision flow control, which minimizes the impact of analysis airflow changes on the analysis.

3.4 Circuit system

The circuit system adopts a large-scale integrated circuit board, and the power supply adopts a solid-state power module. The power module has a short-circuit protection function, which is resistant to current impact, strong anti-interference ability, dust-proof, simple and reliable;

3.5 Detection system

3.5.1 Analysis method:

Oxygen: infrared absorption method, nitrogen: thermal conductivity method, hydrogen: infrared absorption method (or thermal conductivity method)

The use of infrared hydrogen measurement technology can avoid the inherent weakness of the thermal conductivity hydrogen measurement method that it cannot detect nitrogen at the same time, and truly realize the simultaneous detection of three elements of oxygen, nitrogen and hydrogen, and can use high-temperature catalysts instead of expensive normal-temperature catalysts, and the cost of use is low.

3.5.2 Infrared detector:

The integrated solid-state infrared sensor measures oxygen and hydrogen, and infrared detection cells with various ranges are optional. The infrared light source uses high-efficiency, long-life precious metal micro-infrared luminous body and gold-plated metal reflector; the modulation system uses a high-precision stepping motor controlled by a single-chip microcomputer to ensure long-term stability of the modulation frequency, combined with international advanced narrow-band filters and high The precision A/D sampling card makes the whole machine have extremely high detection sensitivity, which can effectively detect the oxygen content of ppm level and the hydrogen content of ppb level. The instrument also uses an advanced temperature-compensated semiconductor detector to reduce the instrument's influence from the outside world and stabilize the baseline signal.

3.5.3 Thermal conductivity detector:

The high-sensitivity thermal conductivity detection cell is adopted, and the cell current is continuously adjustable, thus ensuring that the device has excellent sensitivity and linearity at all stages of the range, combined with high-precision amplifiers and 24-bit A/D sampling cards and other hardware to ensure The accuracy of measuring nitrogen and hydrogen in a large range from ultra-low content to high content. The detection system adopts low-drift, high-precision, large-range, high-sensitivity thermal conductivity detector with low failure rate, strong reliability and good stability.

Application software

English application software based on Windows operating system, PC interface adopts data exchange technology, builds a system working mode of upper and lower computer communication, multi-window, multi-task operation, realizes automatic data storage and ownership in database management Powerful, multi-filtering database search engine, remote database monitoring through the network, dynamic synchronous display of working curves, storage, amplification and multi-level comparison of multiple curves, etc. Dozens of functions.

Main functions of the software

- Quickly display the analysis results and analysis curves;

- The analysis results are automatically stored;

- Automatic input of sample weight;

- Automatic switching between high and low content;

- Real-time monitoring of instrument parameters;

- Automatic alarm when an error occurs;

- Drawing, storage and unloading of dynamic release curve;

- Various correction modes for the analysis results, which can be corrected manually or through the analysis results; single-point correction or multi-point correction;

- Filter the data, calculate the average value, standard deviation, relative deviation, etc.;

- The new software can design several calibration lines according to the user's application, which greatly facilitates the user's use;

- The host computer can be connected with computers, printers, electronic balances, etc. to realize data transmission;

- The analysis time and blank value can be adjusted;

- The user can store several analysis methods for different analysis samples.

- It can store many sample weights (the number is only limited by the capacity of the computer hard disk).

- It can output the result report in formal format.

- It can be connected with the user database to realize the remote transmission of the analysis results, and it is easy to realize the network management of the analysis results.

- It can quickly carry out instrument blank determination.

- The sample number can be stored and edited.

- It can be applied to automatic sample injection to realize the automatic operation of the instrument.

- Equipped with 16 channels, which can be freely configured and used according to the analysis material and content.

Configuration list

SN | ITEM NAME | DESCIRIPTION | QTY |

1 | EA -ONH6 K analyzer host | Pulse electrode furnace: maximum power 8.0KW, maximum temperature 3000℃ Pneumatic system: solenoid valves, cylinders, air pipes, pneumatic joints, etc. Components are imported brand products. Nitrogen detection system: a set of high-sensitivity thermal conductivity detection pool Oxygen detection system: a set of high-sensitivity infrared detector Hydrogen detection system: a set of high-sensitivity infrared detector Or a set of high-sensitivity thermal conductivity detection cell | 1 set |

2 | Electronic balance | LE84E, 1/10,000 precision | 1 set |

3 | microcomputer system | Lenovo M4360 series, 3300 (CPU), 2G memory, 320 hard disk, DVD-ROM | 1 set |

4 | LCD Monitor | 21 inches | 1 set |

5 | printer | HP1106 laser printer | 1 set |

6 | Windows Download analysis software | A set of all Chinese analysis software based on Windows | 1 set |

7 | Random spare parts |

| 1 set |

8 | chiller |

| 1 set |

Service policy

EA -ONH6 K series oxygen, nitrogen and hydrogen analyzer is an analytical instrument with high sensitivity, high precision and high stability. In order to ensure the long-term use of users, and receive reliable technical support, maintenance services and application services. The service guarantee described below will be provided.

Laboratory conditions

1. Laboratory area: about 10 square meters.

2. Laboratory environment: instrument storage temperature: -15°C ~ 40°C

Laboratory temperature when the instrument is working: 20℃~25℃

The human body feels no obvious vibration

No strong magnetic field interference

3. Humidity: ≤80%

4. Air cleanliness: ventilation, no dust, no corrosive gas.

5. Carrier gas:

Purity 99.999% argon (used when detecting oxygen and hydrogen elements)

Purity 99.999% helium (used when detecting nitrogen)

6. Power gas: nitrogen or water-free and oil-free compressed air.

7. Power supply: voltage 220V ± 10%, frequency 50Hz fluctuation < ± 2% (if the voltage is unstable, an overvoltage and undervoltage protection device should be installed), the two sets of power supply are in different phases; one path provides 50A current for pulse heating furnace; The other line is connected to an external three-phase socket, and a set of multiple sockets for computers is prepared, with a maximum current of 10A. Both power supplies must be grounded.

8. Ground wire: separate ground wire, grounding resistance <5 ohms. Voltage to ground is zero volts. Do not share the ground wire with other instruments, nor connect it with the neutral wire of the power supply.

9. Cooling water: 20-40L/min (the tap water pressure is above 0.25MPa, the water quality is good, the hardness is small, the faucet can be connected to a φ10mm water pipe, and there is a sink). An independent external water cooling device is also optional.

10. The overall dimensions of the instrument: length*width*height (mm): 1000*800*1400 (floor type)

11. Users need to prepare a set of computer desks for placing computers, printers and electronic balances.