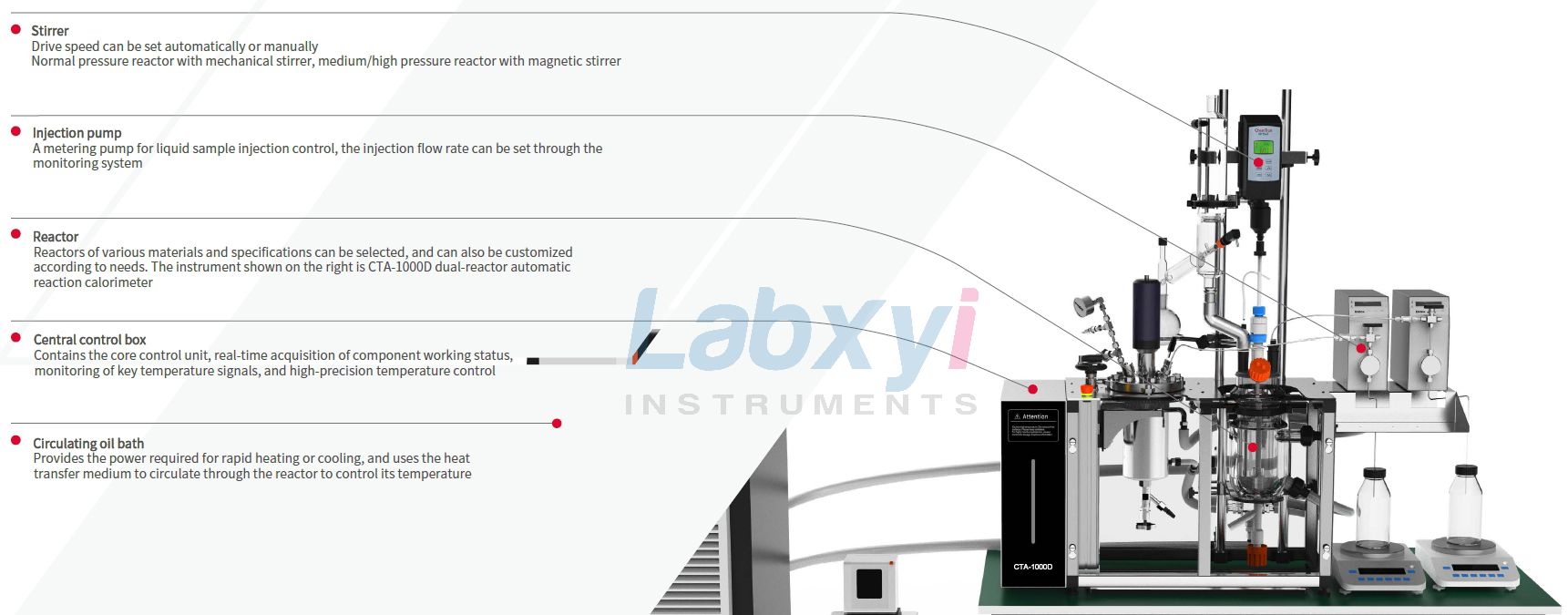

Double kettle automatic reaction calorimeter

CTA-1000D

CTA-1000D double kettle automatic reaction calorimeter is a professional test instrument that simulates the specific process of chemical reaction on a liter scale, measures and controls important process variables. It is an automatic reaction calorimeter under laboratory conditions.

- Remove this product from my favorite's list.

- Add this product to my list of favorites.

Product info

CTA-1000D double kettle automatic reaction calorimeter is a professional test instrument that simulates the specific process of chemical reaction on a liter scale, measures and controls important process variables. It is an automatic reaction calorimeter under laboratory conditions.

Product Introduction

CTA-1000D dual -reactor automatic reaction calorimeter can simulate the real situation of batch or semi-batch reactions in factories, and is widely used in reaction process design, process optimization and amplification, process safety assessment, etc. in the fields of fine chemicals, pharmaceuticals, and third-party safety assessment. The instrument is designed mainly for diversified process development and hazard assessment needs. It can adapt to both normal pressure and pressurized reactions, and meet the needs of corrosive material testing. The dual- reactor shares an oil bath and a central controller. The oil circuit realizes rapid switching between the two reactors through valves . There is no need to disassemble the oil circuit to drain the silicone oil in the jacket. The operation is simple and fast, and the instrument is highly integrated.

Features

1) It has three calorimetric methods: heat flow, power compensation, and reflow. Users can choose according to their needs

2) Support multiple operation modes such as isothermal, constant temperature, scanning, etc.

3) Optional atmospheric pressure kettle and high pressure kettle or atmospheric pressure kettle and medium pressure kettle

4) The two kettles are fixed by a stand, sharing the oil bath, central control and reflux device, etc., with high integration

5) The double kettles switch the jacket oil circuit through valves, which eliminates the need for disassembly and repeated oil heating, making the operation simple and fast

6) High-power heating and cooling units, fast temperature control response speed, high heat release measurement accuracy

7) It has automatic feeding control for gas, liquid and other materials, and can measure by mass, volume or pressure

8) Accurately measure and obtain process safety related data such as reaction heat flow, reaction enthalpy, conversion rate, sample specific heat capacity, adiabatic temperature rise, and the maximum temperature that the out-of-control system can reach.

9) Chinese software platform, built-in hardware database compatible with more peripherals with different characteristics, flexible programming of experimental processes, real-time monitoring of key data of the reaction process, and online modification of experimental processes and parameters

10) Real-time display of test status such as kettle temperature, jacket temperature, feed mass, stirring speed, pressure, inlet/exhaust speed, pH, inlet and outlet temperatures of the reflux device, etc.

11) Key parameters and status safety thresholds can be set. When the reaction is out of control, "one-click" rapid cooling, abnormal state alarm and automatic shutdown can be performed to effectively ensure safety.

12) Automatically generate and save charts and data, and export experimental analysis reports

MODEL | CTA-1000D |

Calorimetric method | Heat flow method, power compensation method (optional), reflow method (optional) |

temperature control |

|

Kettle body temperature range | -25℃~200℃ |

Oil bath temperature range | -45℃~250℃ |

control method | Isothermal, Constant Temperature, Scanning |

Temperature resolution | 1.0mK |

Sample temperature control precision | ±0.1K |

Silicone oil circulation speed | 35L/min~76L/min |

Power Control |

|

Driver voltage range | 0~50VDC |

Driver maximum current | 3.0A |

Heater maximum power | 120W |

Atmospheric pressure glass reactor (optional) |

|

Reactor volume | 1000mL, other volumes can be customized |

Work Pressure | Atmospheric pressure |

Reactor material | Glass |

Medium pressure glass reactor (optional) |

|

Reactor volume | 1000mL, other volumes can be customized |

Work Pressure | 0.6MPa or 1.2MPa |

Reactor body material | Glass |

Reactor cover material | 316L stainless steel or Hastelloy |

High pressure metal reactor (optional) |

|

Reactor volume | 1000mL, other volumes can be customized |

Work Pressure | 10MPa |

Reactor material | 316L stainless steel or Hastelloy |

Mixer |

|

Maximum speed | 2000r/min, 3000r/min optional |

Maximum Torque | 75N·cm, optional 300N·cm |

Stirring paddle type | Anchor or paddle |

Material of stirring paddle | PTFE, 316L or Hastelloy |

Injection system |

|

Injection channel | 1 liquid inlet, 1 solid inlet, 1 gas inlet; the inlet can be expanded to 4 |

Precision balance | Range 3100g, accuracy 0.01g |

Injection pump | Medium pressure pump: electromagnetic diaphragm pump, maximum flow rate 2L/h |